- Aluminum Composite Panel

- Concrete Floor Steel Decking

- Purlins

- Versafence

It has a high degree of levelness to preserve the fine architectural design ans can be roller bended to suit various design shapes.

| Thickness : | 3 mm |

| 4 mm | |

| 5 mm | |

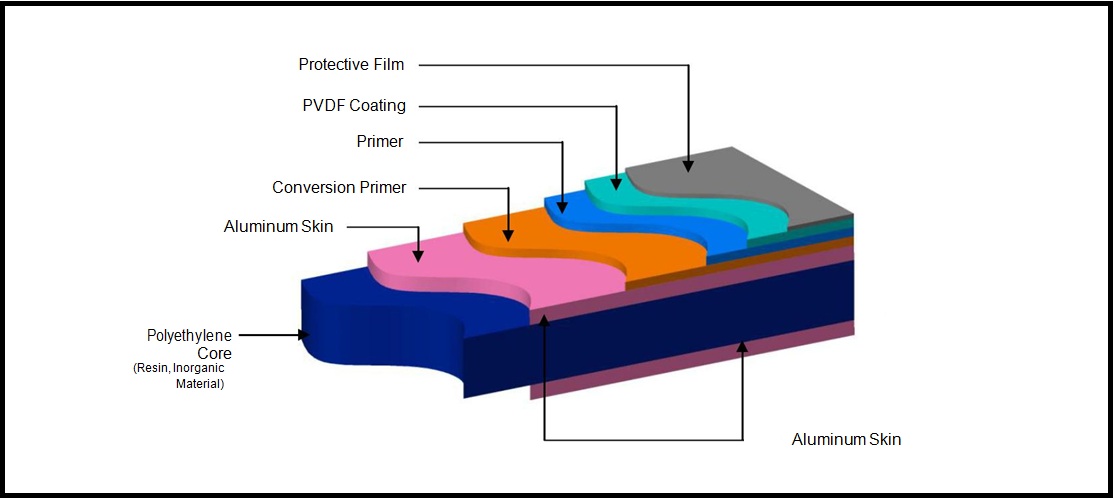

| Coating : | Polyester |

| PVDF (Polyvinynilidine Flouride) | |

| PVDF (Polyvinynilidine Flouride) + NANO | |

| Fire Rated Panels |

APPLICATIONS:

- Interior & Exterior material of building

- Structure of exhibit hall

- Advertisement boards

- Factory Buildings

- Bath, washroom & simple frame wall, etc.

- Cladding of buildings situated in a highly corrosive environment. ( e.g. project near the seashore)

General Properties

| Testing Item | Standard | Result |

|---|---|---|

| Unit weight | ASTM D792 | t3mm=4.6kg/m2 t4mm=5.5kg/m2 |

| Outdoor temperature resistance | ASTM D1654 | No abnormity |

| Thermal expansion | ASTM D696 | 3.0×10-5 -1 |

| Thermal deformation temperature | ASTM D648 | 115 |

| Thermal conduction | ASTM 976 | 0.102Kcal/m.hr |

| Flexural rigidity | ASTM C393 | 14.0×105 |

| Impact resistance | ASTM D732 | 1.650kgf |

| Adhesive strength | ASTM D903 | 0.74kgf/mm |

| Sound-insulating rate | ASTM E413 | 29 |

| Flexural Elasticity | ASTM D790 | 4055kg/mm2 |

| Shear resistance | ASTM D732 | 2.6kgf/mm2 |

| Minimum bending radius | ASTM D790 | 45mm 70mm |

| Fire propagation | ASTM E84 | Qualified |

| Smoke developed | ASTM E84 | <45 |

| Wind-pressure resistance | ASTM E330 | Passed |

| Properties against water | ASTM E331 | Passed |

| Properties against air | ASTM E283 | Passed |

PVDF Coating Finish

| Testing Item | Standard | Result |

|---|---|---|

| Finish coat thickness | ISO 2360(CNS 8406)º | 27.6m |

| Gloss | ASTM D532-89 | 20~45% |

| Pencil hardness | ASTM D3363-00 | 2H |

| Toughness | ASTM D4145-83 | 2T no rift |

| Adhesive force | ASTM 3359-97 | 4B |

| Impact resistance | ASTM D2794-93 | >100kg.cm |

| Abrasion resistance | ASTM D968-93 | 64.6 L/mil |

| Mortar resistance | ASTM 605.2-90 | 24 Hrs pat test exceed |

| Humidity resistance | ASTM D714-97 | 3000hr No blister |

| ASTM D2247-02 | ||

| Boiling-water resistance | ASTM D3359-B | Passed |

| Salt-spray resistance | ASTM D117-03 | 3000hr No blister |

| Acid resistance | ASTM D1308-87 | No Effect |

| AAMA 605.2-91,TEST#7,7.31 | ||

| Alkali resistance | ASTM D1308-87 | Passed |

| Solvent resistance | ASTM D2248-73 | Passed |

| ECCA T5&NCCA NO.11-18 | ||

| Color retention | ASTM D2244-93 | E=0.34 |

| Chalk resistance | ASTM D4214-98 | No Chalking |

| Gloss retention | ASTM D2244-93 | 84.20% |

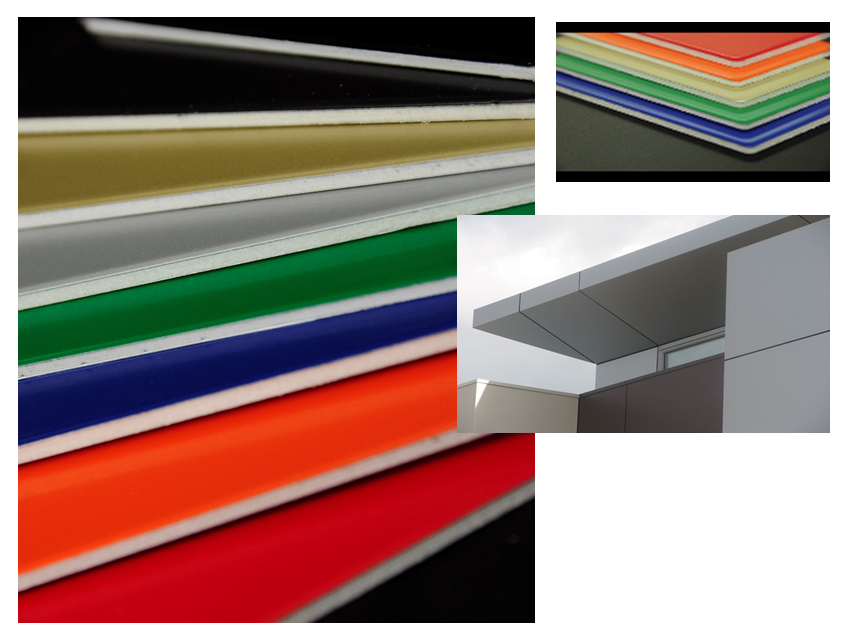

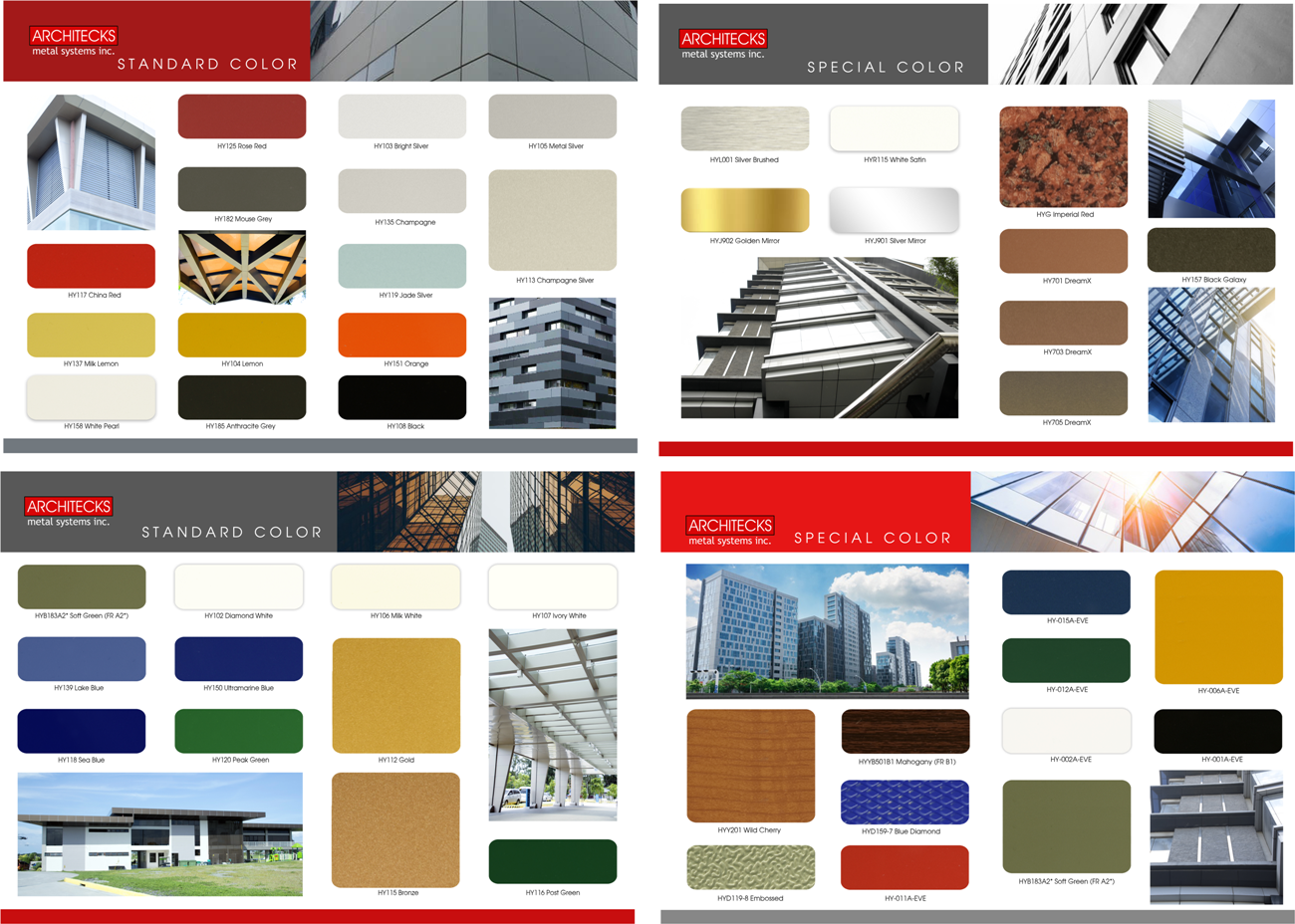

Color Chart

Characteristics of Aluminum Composite Panel

Lightweight

ACP only weighs 5.6kg/m2. Definitely lighter than other cladding materials such as granite and marble. It can reduce structure members.

Durability

Aluminum Composite Panel is highly resistant to chemical corrosion due to the advance Fluoroplastic coating of polyvinilydine fluoride (PVDF), the composite material is rigid, resistant to blows, breakage and pressure and has a high bending and breaking strength.

Flatness

As the composite material is rigid, the flat surface be preserved. This is considered a major advantage of ACP.

Fire Resistance

ACP are laminated at the temperatures from 200 °C to 250 °C to bond the aluminum sheets to the PE Core. The non-flammable cover sheets protect the plastic core.

Material Composition

ARCHITECKS panel is painted with an advance fluorocarbon paint (PVDF) a durable coating on Aluminum laminated composite material. The laminated structure of ACP ensures exceptional strength of the panel.

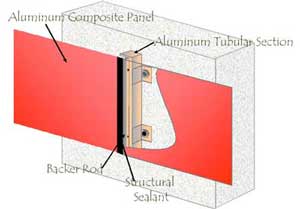

Installation Details

Horizontal Section

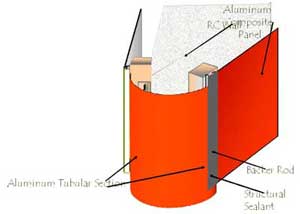

Round Section

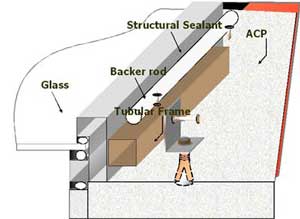

Panel and Window Section

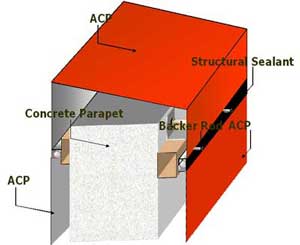

Coping Section

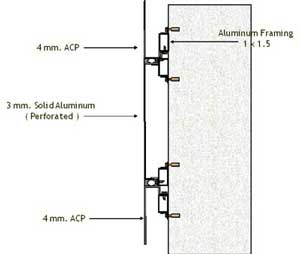

Connection of Perforated Panel

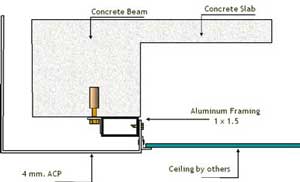

Connection of ACP to Ceiling

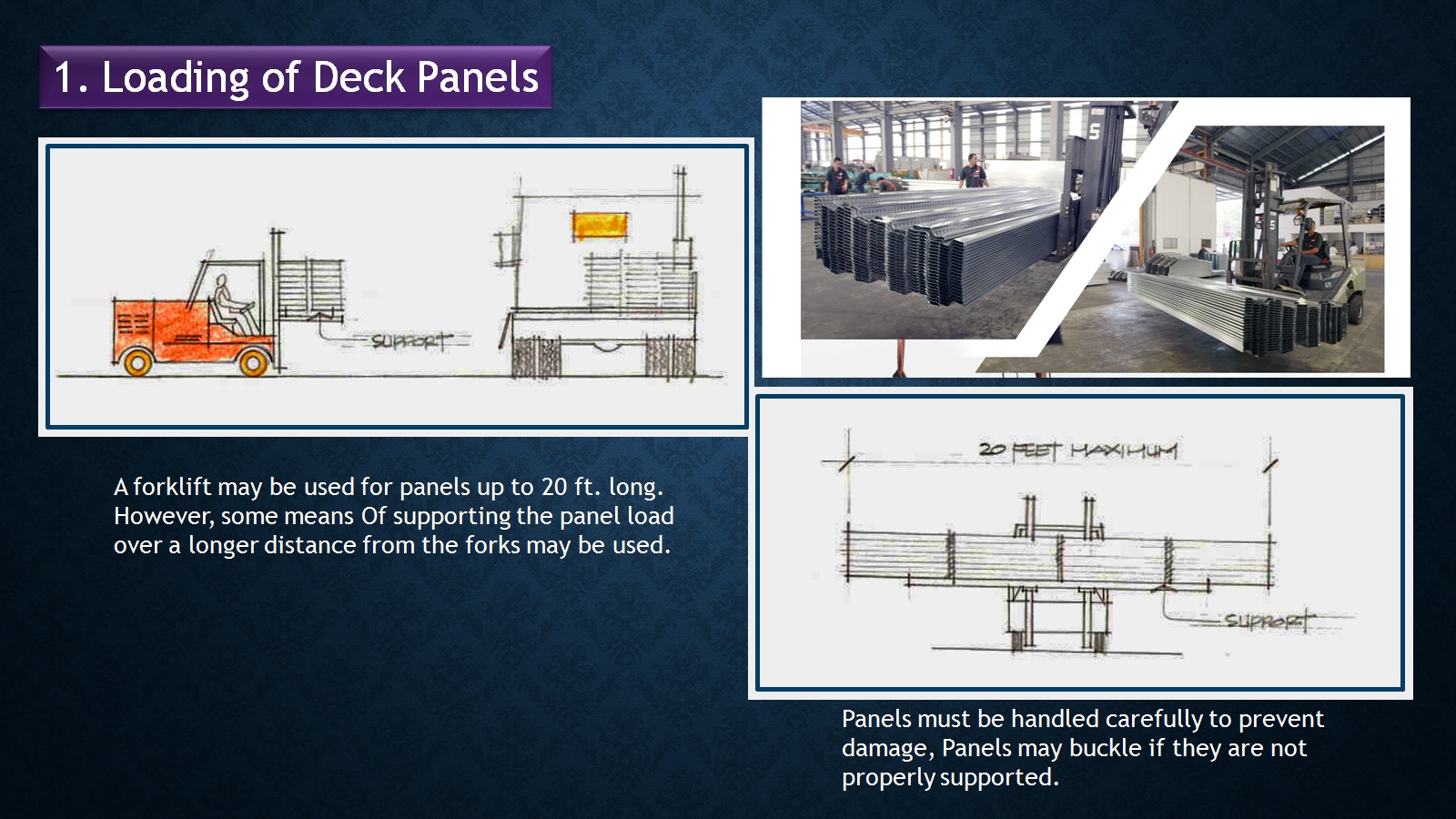

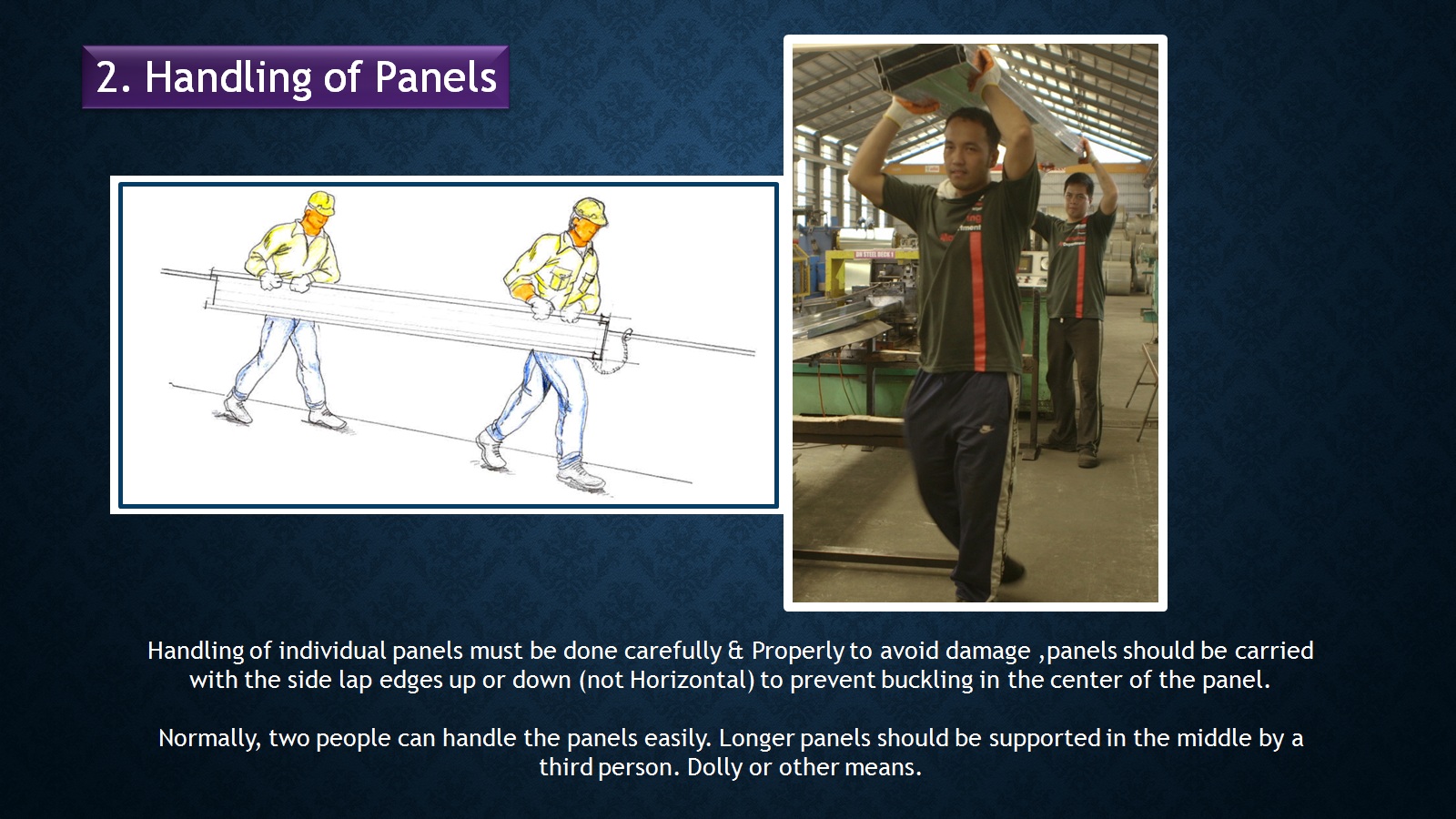

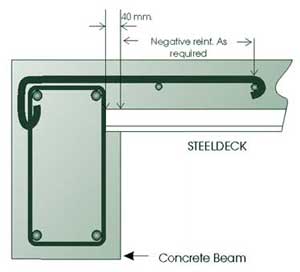

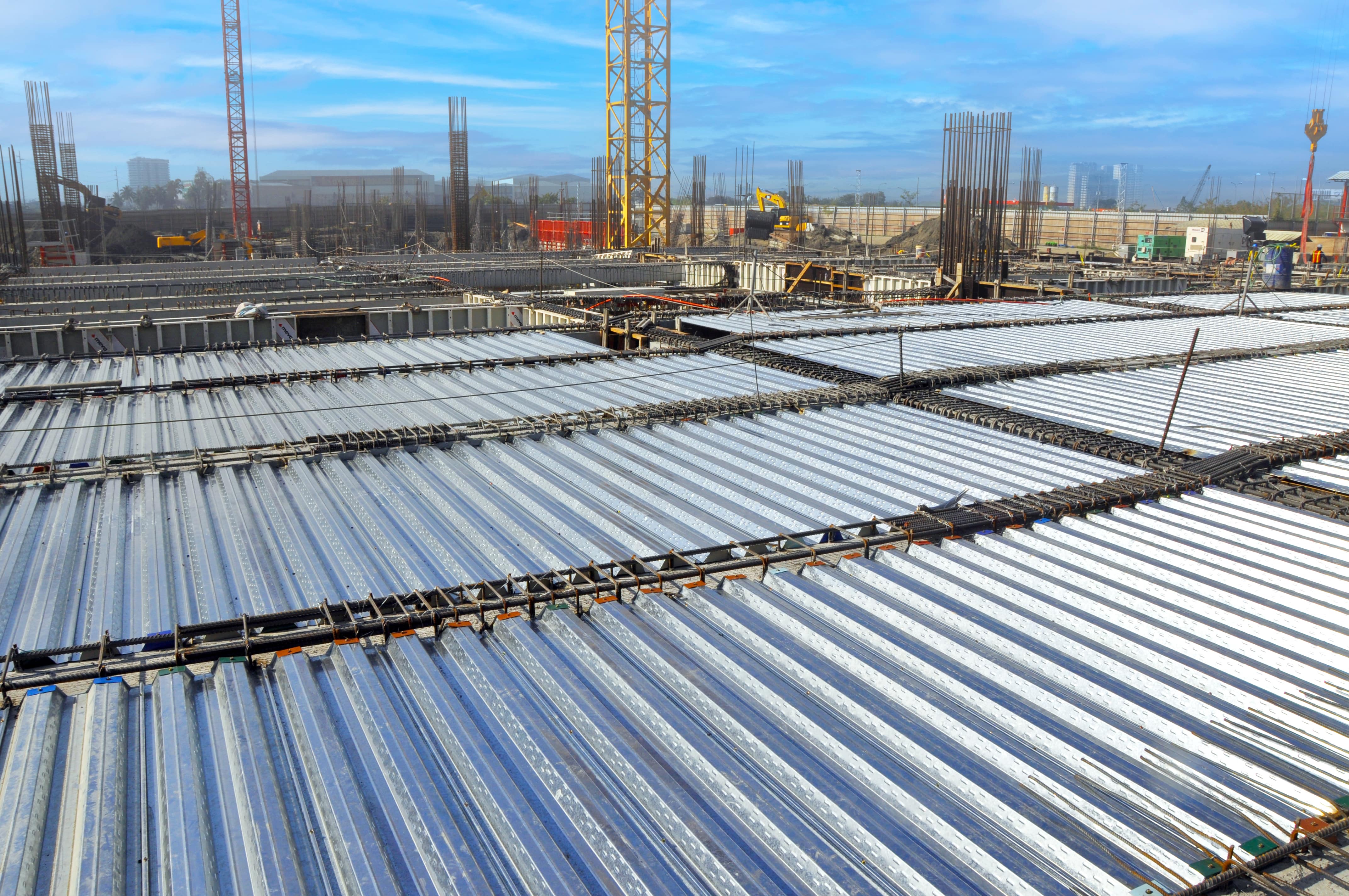

It is used to support concrete of a Concrete Slab. It was developed to provide a structurally efficient product for use in floor systems.

It is designed to create a permanent formwork that replaced the conventional wood forms that are used in Hanging Slabs.

Despite the fact that it is a structural component, its uniform quality can offer an attractive appearance, especially with the use of properly specified shop and field applied coatings.

Steel deck is also a component of many UL and ULC approved fire rated assemblies.

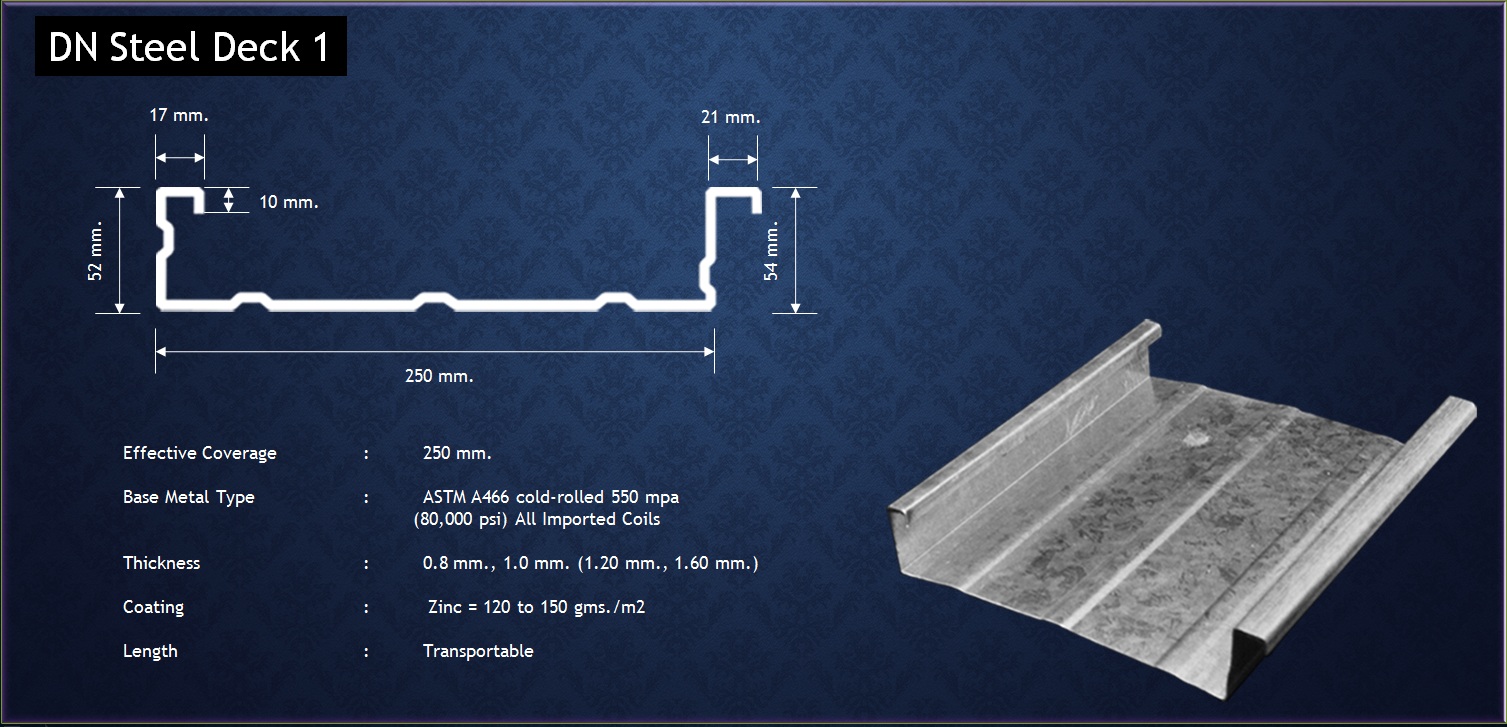

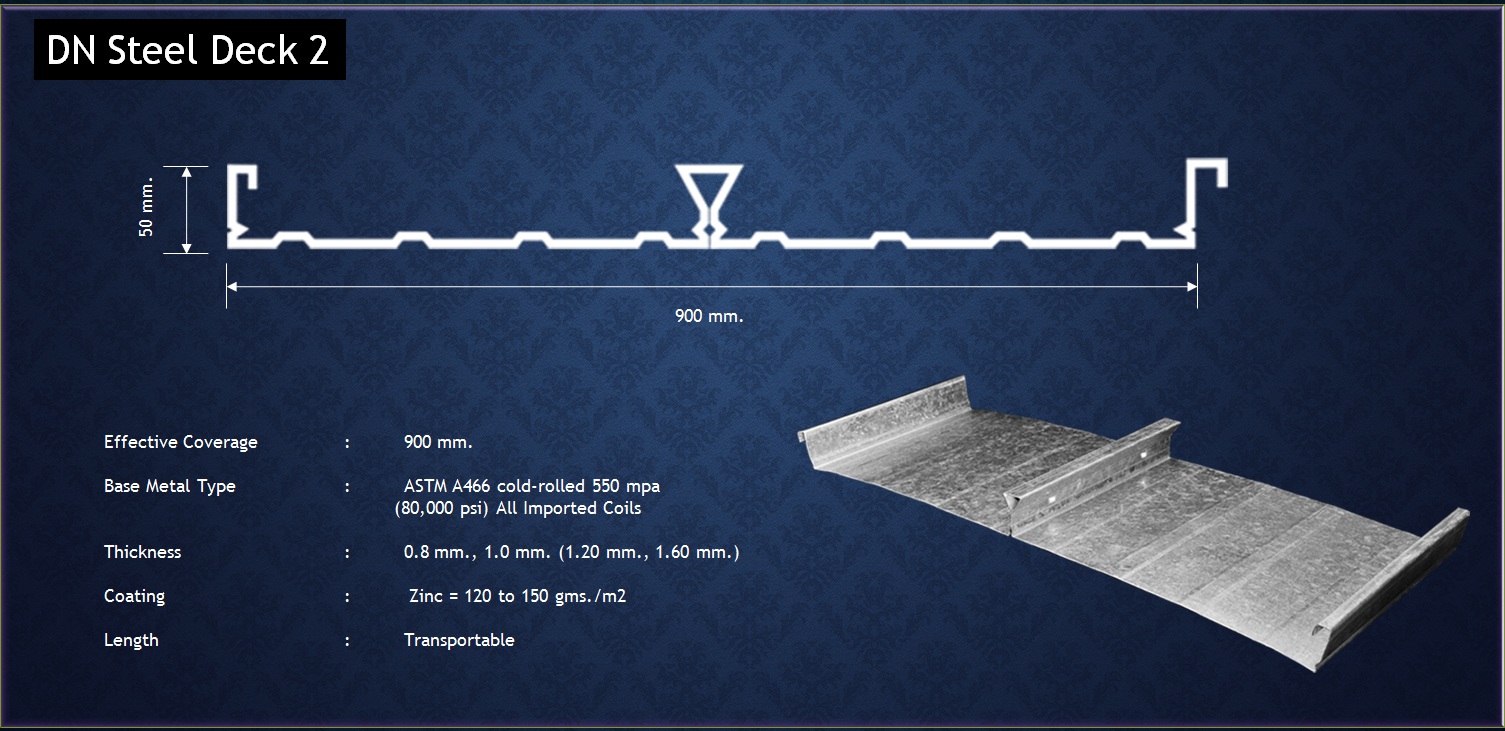

Specifications

| Base metal type | : | ASTM A466 cold-rolled |

| 550 mpa (80,000 psi) | ||

| (Available in Local & Imported coils) | ||

| Now available in prepainted for Steel Deck One | ||

| Thickness | : | 0.80 mm |

| 1.00 mm | ||

| 1.20 mm | ||

| 1.60 mm | ||

| Coating | : | Imported Coil – Zinc = 275 gms / m2 |

| Local Coil – Zinc = 120 to 150 gms / m2 | ||

| Length | : | Transportable |

DECK ONE

| Steel Section Properites | ||||

| t (mm.) |

y (mm.) |

I (mm.mm) |

St (mm3) |

Sb (mm3) |

| 0.80 1.00 |

13.02 13.13 |

122046.73 151745.35 |

3300.29 4115.99 |

9374.25 11554.72 |

| Composite Section Properties | ||||||

| t (mm.) |

y (mm.) |

x (mm.) |

I (mm.mm) |

St (mm3) |

Sb (mm3) |

|

| 0.80 | 100 125 150 |

2901.60 | 34.80 40.68 45.96 |

11412549.66 20361085.33 32129244.80 |

327924.61 500491.83 699000.72 |

175045.44 241480.14 308829.74 |

| 1.00 | 100 125 150 |

3627.00 | 37.75 44.28 50.16 |

13233160.46 23803316.49 37785304.16 |

350536.32 537523.02 753310.42 |

212584.93 294899.68 378454.82 |

| Maximum allowable superimposed load (80,000 psi) design for 33,000 psi tensile strength is also available |

|||||||||

| I (mm.) |

Maximum allowable superimposed load, kPa | ||||||||

| span (m) | |||||||||

| 1.50 | 1.80 | 2.00 | 2.30 | 2.50 | 2.80 | 3.00 | 3.50 | ||

| 0.80 | 100 125 150 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

10.01 12.00 12.00 |

8.41 12.00 12.00 |

4.88 9.14 12.00 |

| 1.00 | 100 125 150 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

10.85 12.00 12.00 |

9.13 12.00 12.00 |

6.02 10.01 12.00 |

|

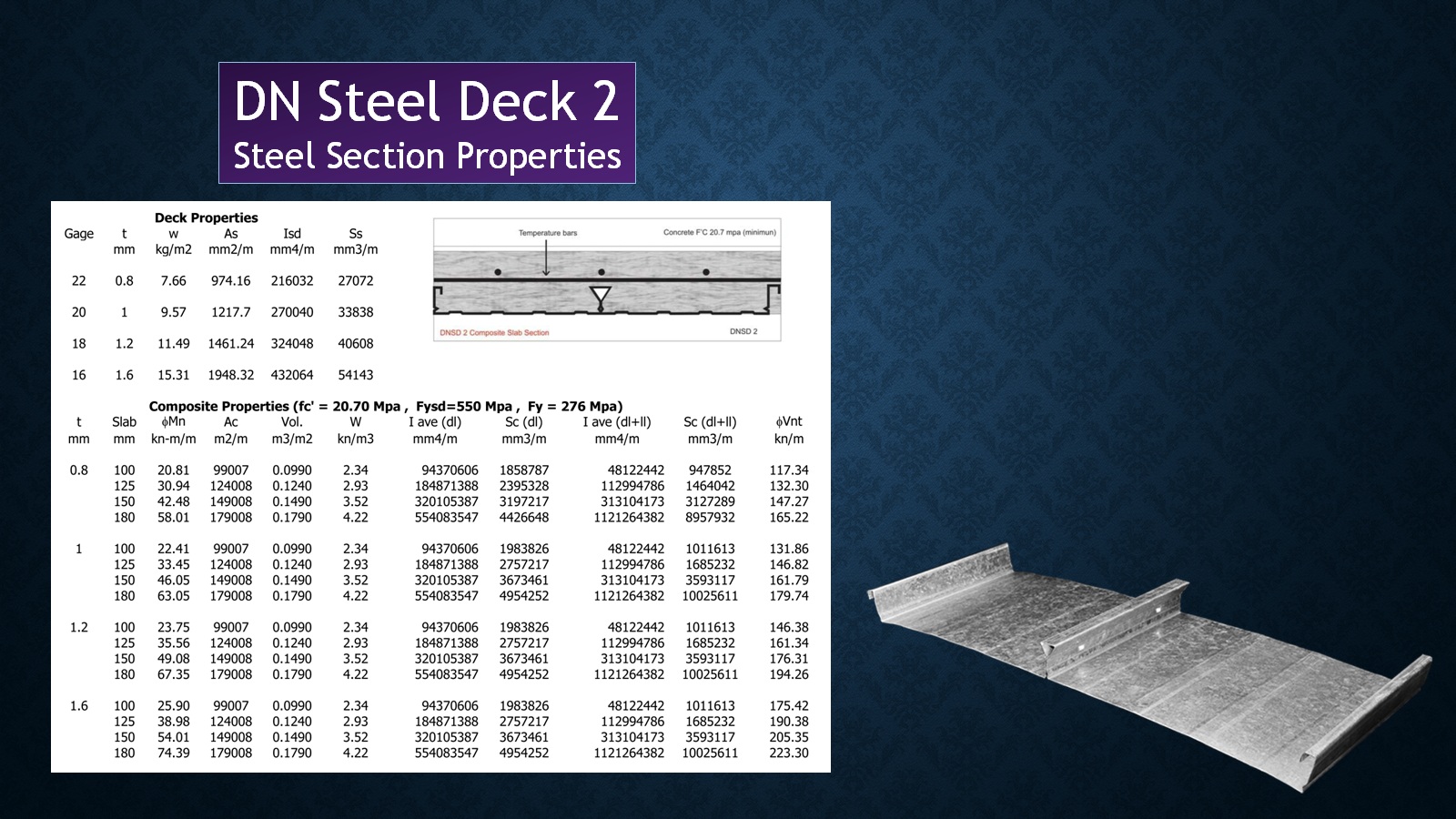

DECK TWO

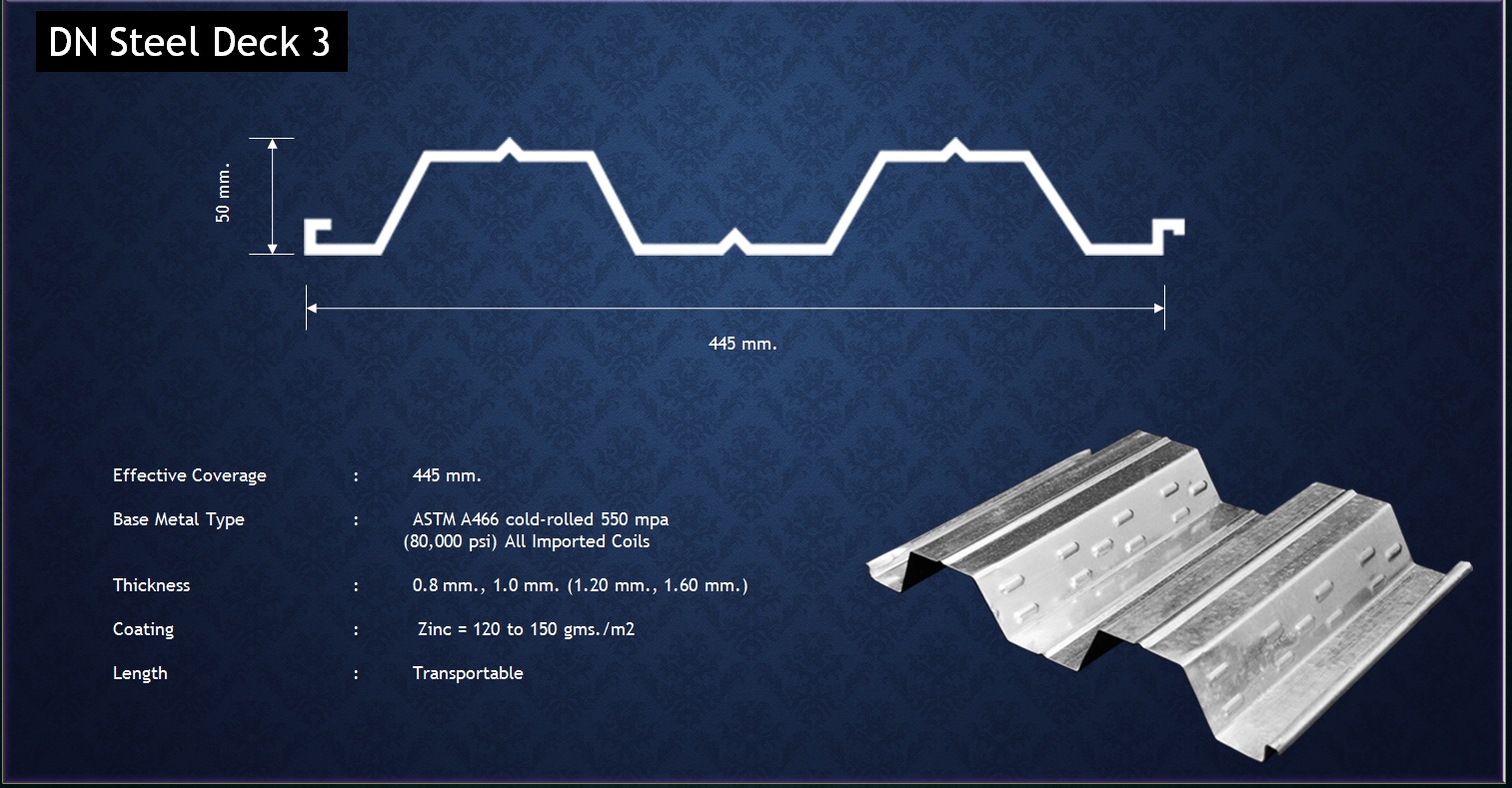

DECK THREE

| Steel Section Properites | |||||

| t (mm.) |

W (kg/mm.) |

A (mm2/mm) |

I (mm4/mm) |

St (mm3) |

Sb (mm3) |

| 0.80 1.00 1.20 1.40 1.60 |

8 10 12 14 16 |

1.083 1.353 1.624 1.895 2.165 |

401.477 515.760 639.319 774.008 921.684 |

19.915 25.583 31.712 38.393 45.718 |

13.454 17.284 21.425 25.939 30.888 |

| Maximum allowable superimposed load .Kpa | |||||||||

| I (mm.) |

Slab DEPTH (MM.) |

span (m) | |||||||

| 1.50 | 1.80 | 2.00 | 2.30 | 2.50 | 2.80 | 3.00 | 3.50 | ||

| 0.80 | 100 125 150 |

19.20 19.20 19.20 |

19.20 19.20 19.20 |

15.95 19.20 19.20 |

12.70 17.69 19.20 |

9.73 13.57 17.60 |

7.48 10.45 13.58 |

6.35 8.88 11.55 |

4.31 6.05 7.90 |

| 1.00 | 100 125 150 |

19.20 19.20 19.20 |

19.20 19.20 19.20 |

15.10 19.20 19.20 |

15.10 19.20 19.20 |

11.62 16.48 19.20 |

8.99 12.78 16.77 |

7.66 10.90 14.32 |

4.91 7.54 9.93 |

| 1.20 | 100 125 150 |

19.20 19.20 19.20 |

19.20 19.20 19.20 |

18.97 19.20 19.20 |

18.97 19.20 19.20 |

14.67 19.20 19.20 |

10.54 15.95 19.20 |

3.57 13.67 17.79 |

5.40 9.57 12.48 |

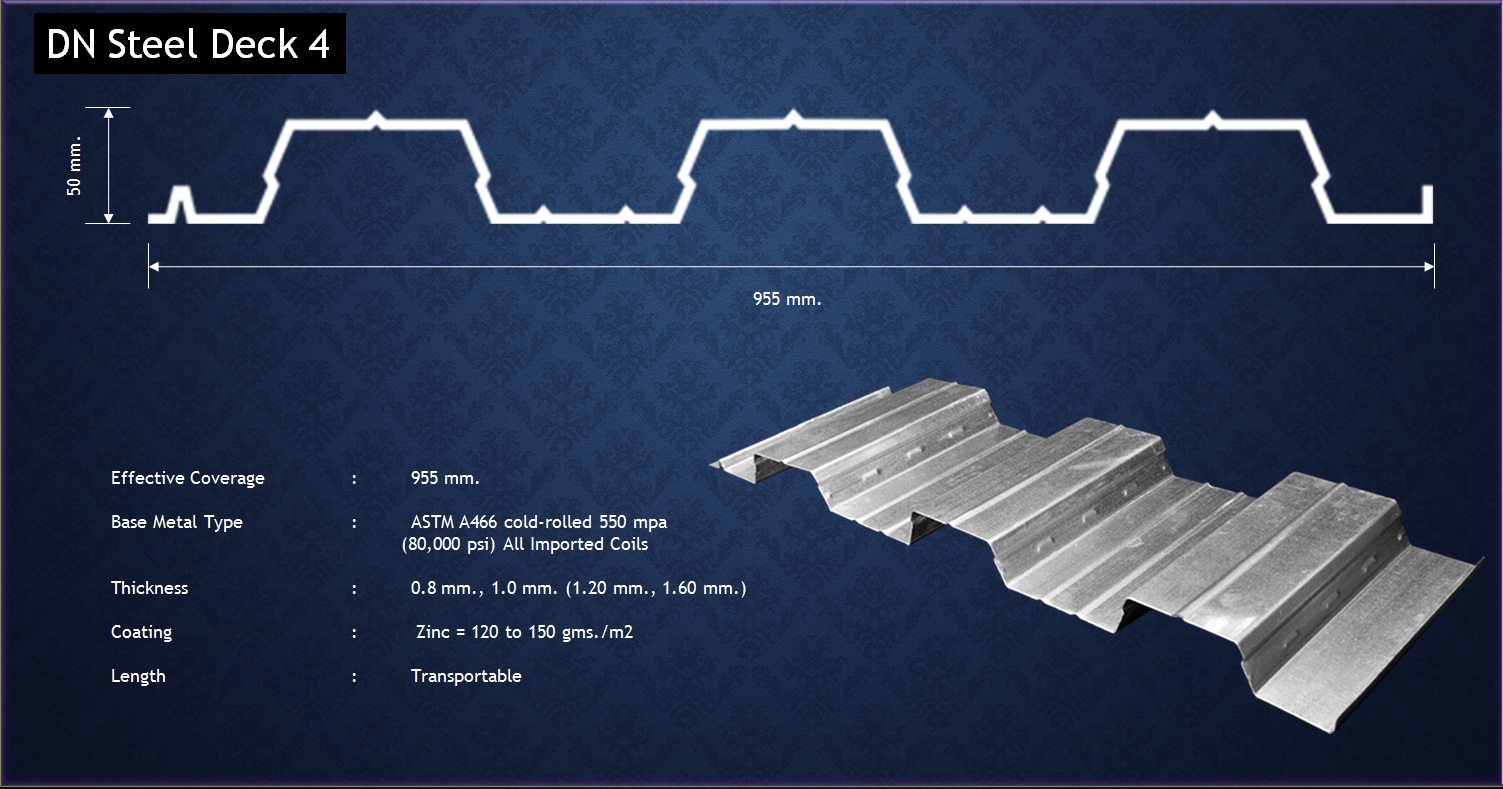

DECK FOUR

| Deck Properites | ||||||||

| Gauge | t (mm.) |

W (kg.m2 |

A mm2/mm |

I mm4/mm |

Sp mm2/mm |

Sn mm2/mm |

Rb kN/m |

oVn kN/m |

| 22 | 0.8 | 8 | 1.021 | 518 | 23.4 | 18.6 | 11.929 | 27.88 |

| 20 | 1.0 | 10 | 1.276 | 648 | 29.2 | 23.3 | 16.995 | 33.76 |

| 18 | 1.2 | 12 | 1.532 | 777 | 35.1 | 27.9 | 28.779 | 44.55 |

| 16 | 1.6 | 16 | 2.042 | 1037 | 46.8 | 37.2 | 42.778 | 55.9 |

| Composite Properties | |||||||||

| t mm. |

Slab Depth mm. |

OM kN.m. |

A m2/m. |

Vol M2/m2 |

W kN/m2 |

Sc mm3/m |

Iave mm4/m |

oM kN.m |

oV kN/m |

| 0.80 | 100 125 150 180 |

16.68 22.64 28.61 35.77 |

0.059 0.079 0.099 0.126 |

0.077 0.102 0.127 0.157 |

1.815 2.402 2.990 3.695 |

54507 75372 97490 124960 |

5792014 11151680 18953266 32128000 |

12.47 17.62 22.79 29.21 |

38.312 50.410 62.853 72.245 |

| 1.00 | 100 125 150 180 |

20.25 27.70 35.16 44.11 |

0.059 0.079 0.099 0.126 |

0.077 0.102 0.127 0.157 |

1.815 2.402 2.990 3.695 |

66653 92341 119684 153720 |

6312754 12066492 20408851 34432764 |

15.58 21.59 27.98 35.93 |

38.312 50.410 63.517 78.125 |

| 1.20 | 100 125 150 180 |

23.59 32.54 41.50 52.24 |

0.059 0.079 0.099 0.126 |

0.077 0.102 0.127 0.157 |

1.815 2.402 2.990 3.695 |

78488 108910 141414 181962 |

6800543 12924654 21779514 36613265 |

18.35 25.46 33.06 42.53 |

38.312 50.410 63.517 80.576 |

| t (mm.) |

Slab Depth mm. |

OM kN.m. |

Uniforem Superimposed Loads, kn/m2 | ||||||

| span (m) | |||||||||

| 2.0m | 2.5m | 3.0m | 3.5m | 3.75m | 4.0m | 4.5m | |||

| 0.80 | 100 125 150 180 |

12.74 17.62 22.79 29.21 |

14.57 19.2 19.2 19.2 |

8.83 12.29 15.99 19.2 |

5.72 7.99 10.42 13.46 |

3.84 5.39 7.06 9.15 |

3.17 4.46 5.86 7.61 |

2.62 3.7 4.88 6.36 |

1.79 2.55 3.34 4.44 |

| 1.00 | 100 125 150 180 |

15.58 21.59 27.98 35.93 |

18.11 19.2 19.2 19.2 |

11.1 15.5 19.2 19.2 |

7.3 10.19 13.94 17.19 |

4.99 7.01 9.62 11.9 |

4.18 5.87 8.08 10.1 |

3.51 4.94 6.82 8.46 |

2.49 3.53 4.9 6.1 |

| 1.20 | 100 125 150 180 |

18.35 25.46 33.06 42.53 |

19.2 19.2 19.2 19.2 |

13.32 18.56 19.2 19.2 |

8.83 12.34 16.9 19.2 |

6.13 8.59 11.8 14.59 |

5.16 7.25 9.98 12.35 |

4.37 6.15 8.49 10.52 |

3.17 4.48 6.22 7.73 |

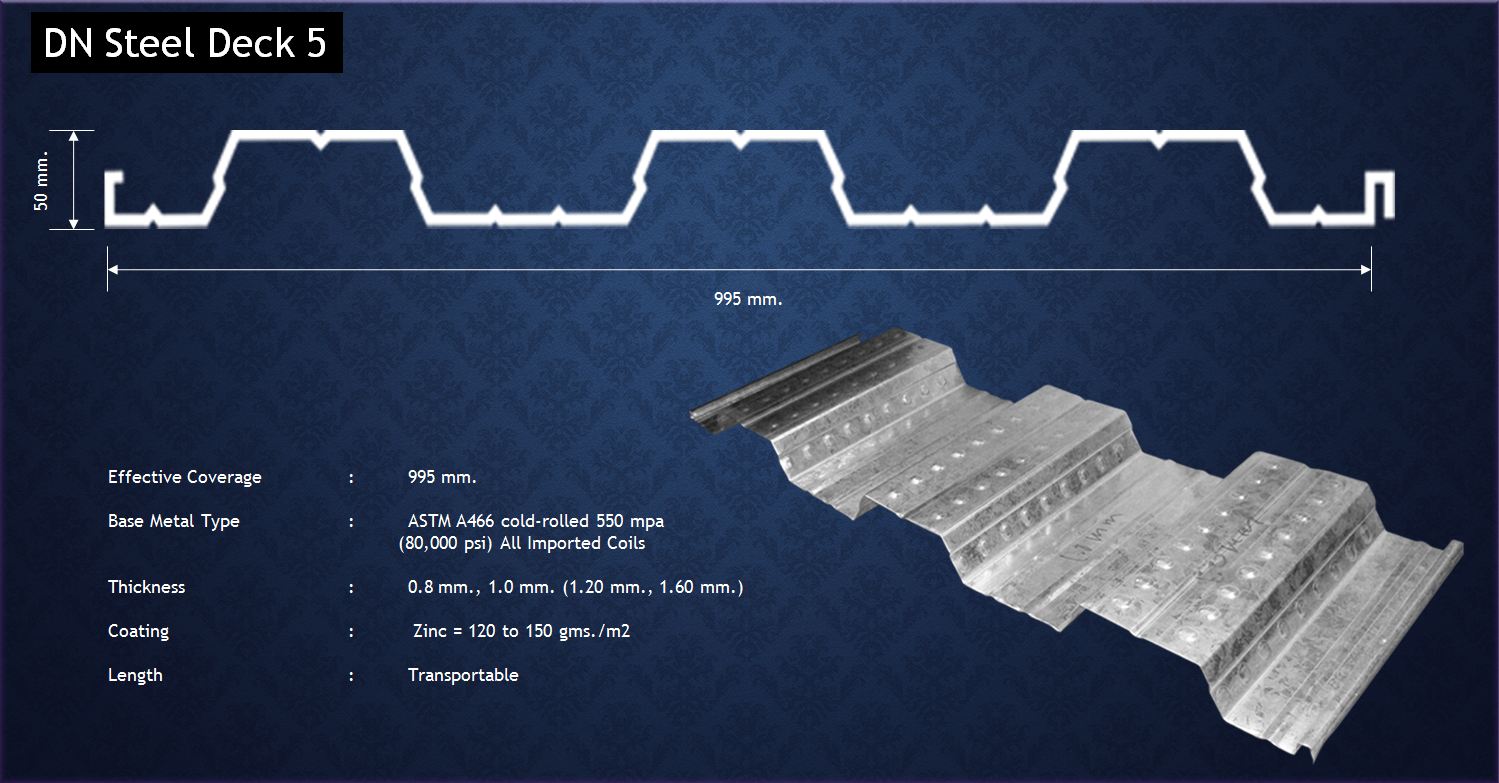

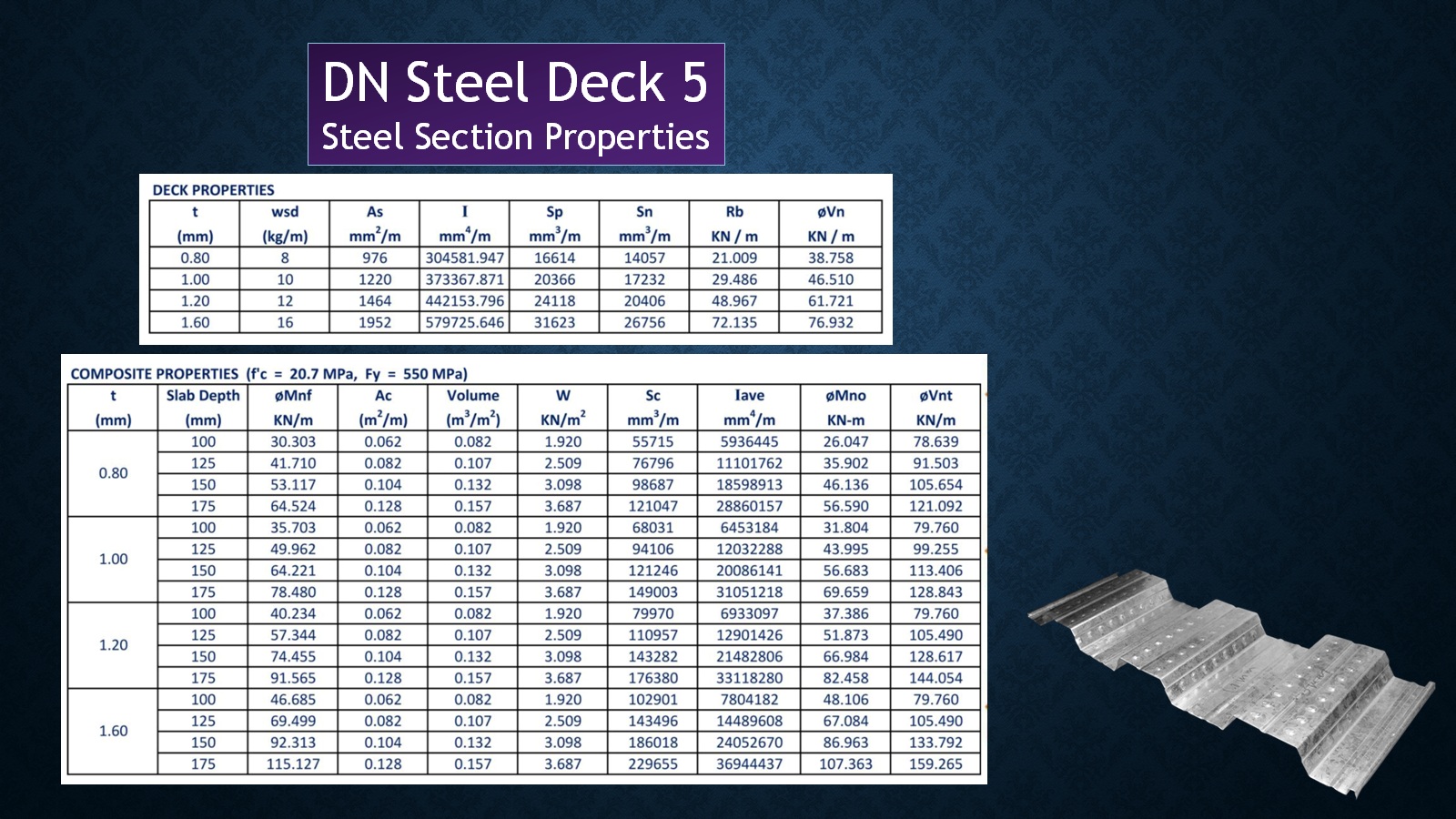

DECK FIVE

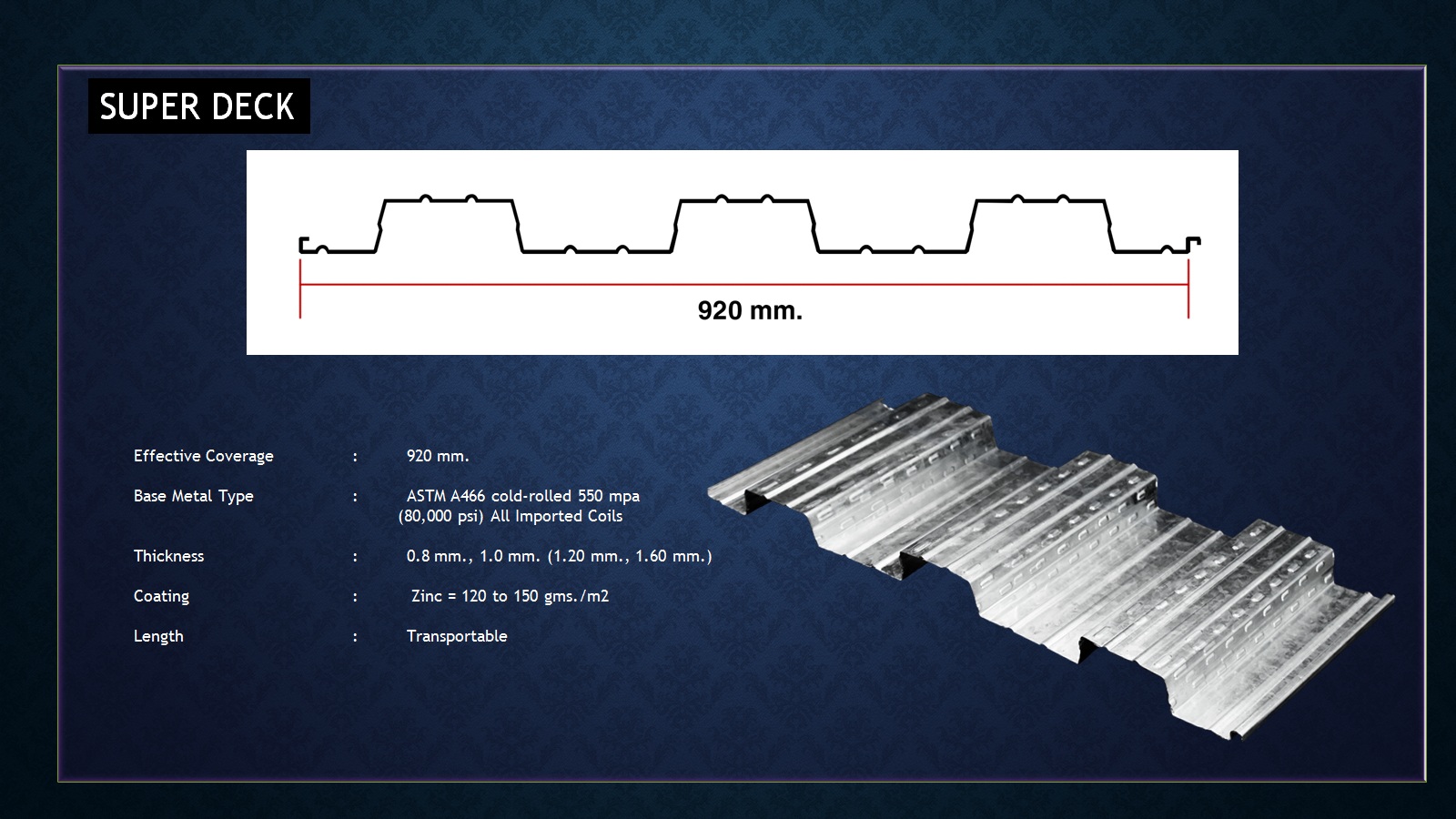

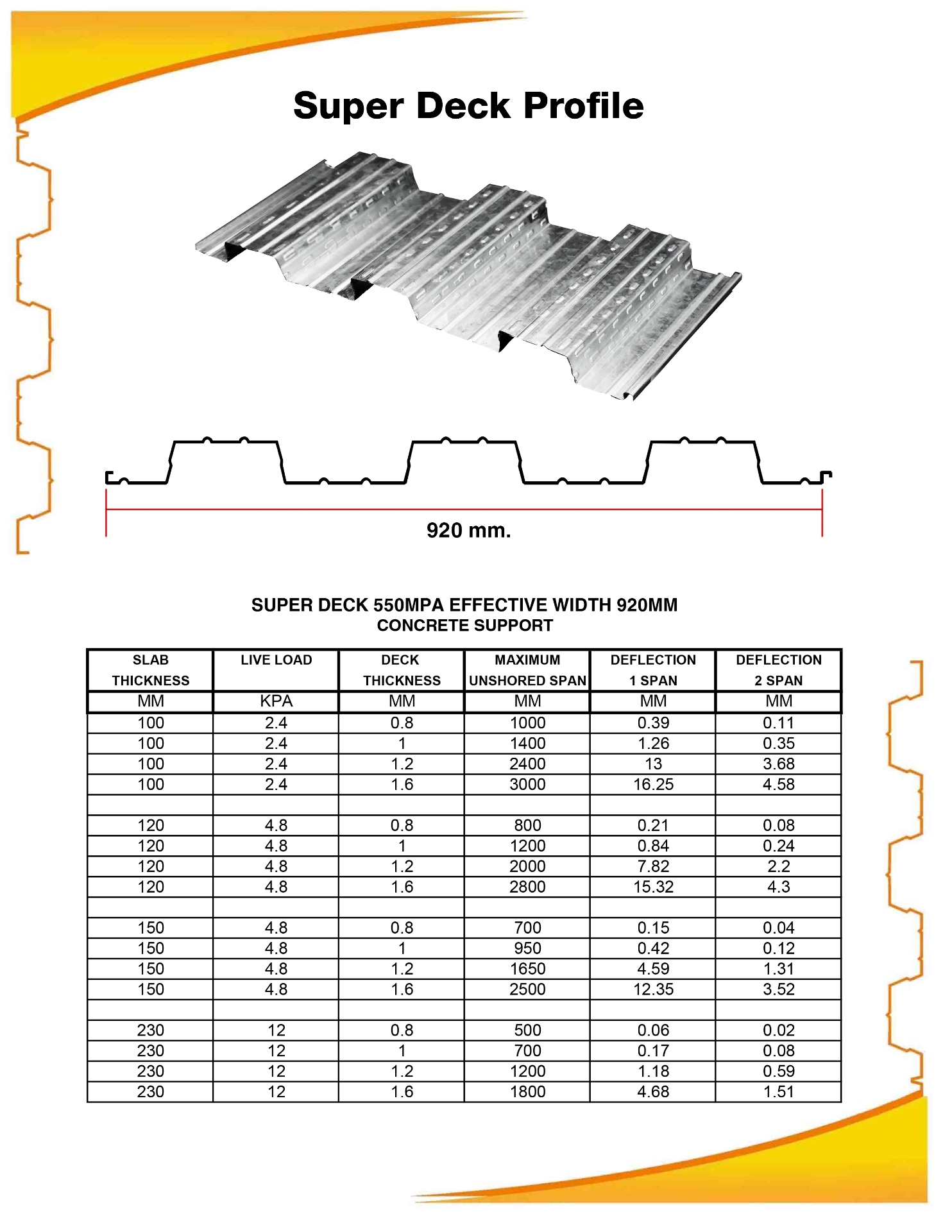

SUPER DECK

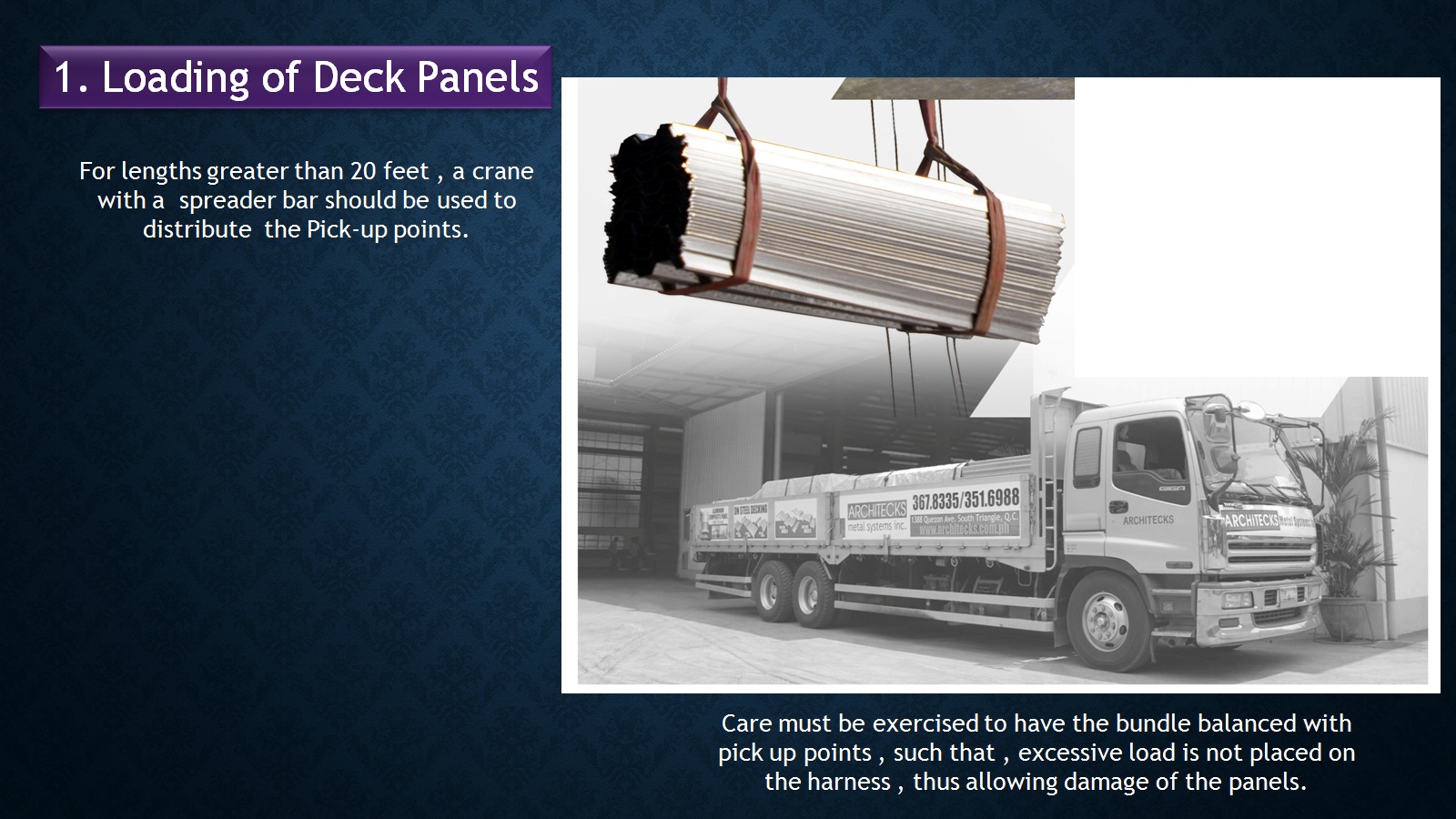

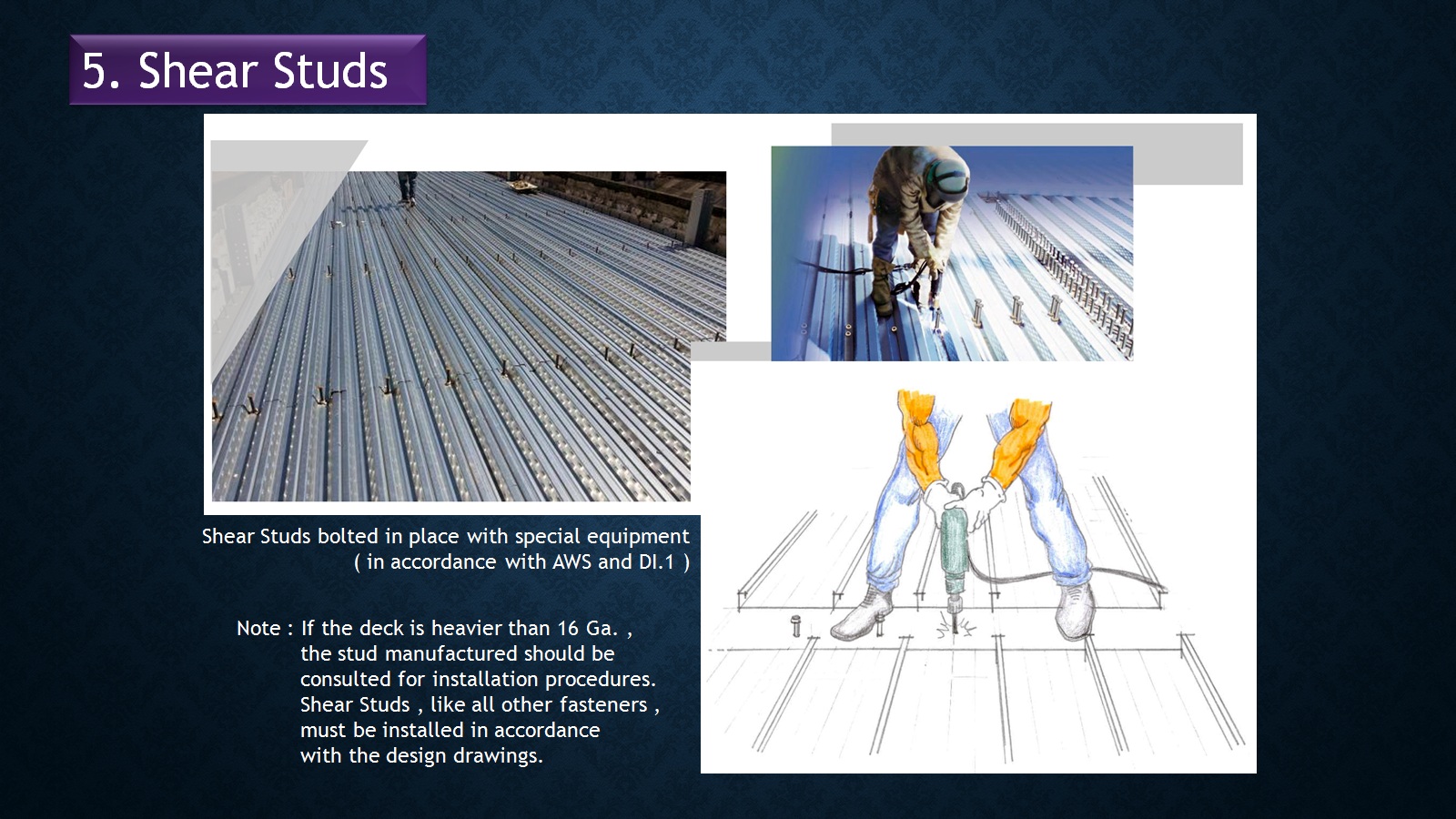

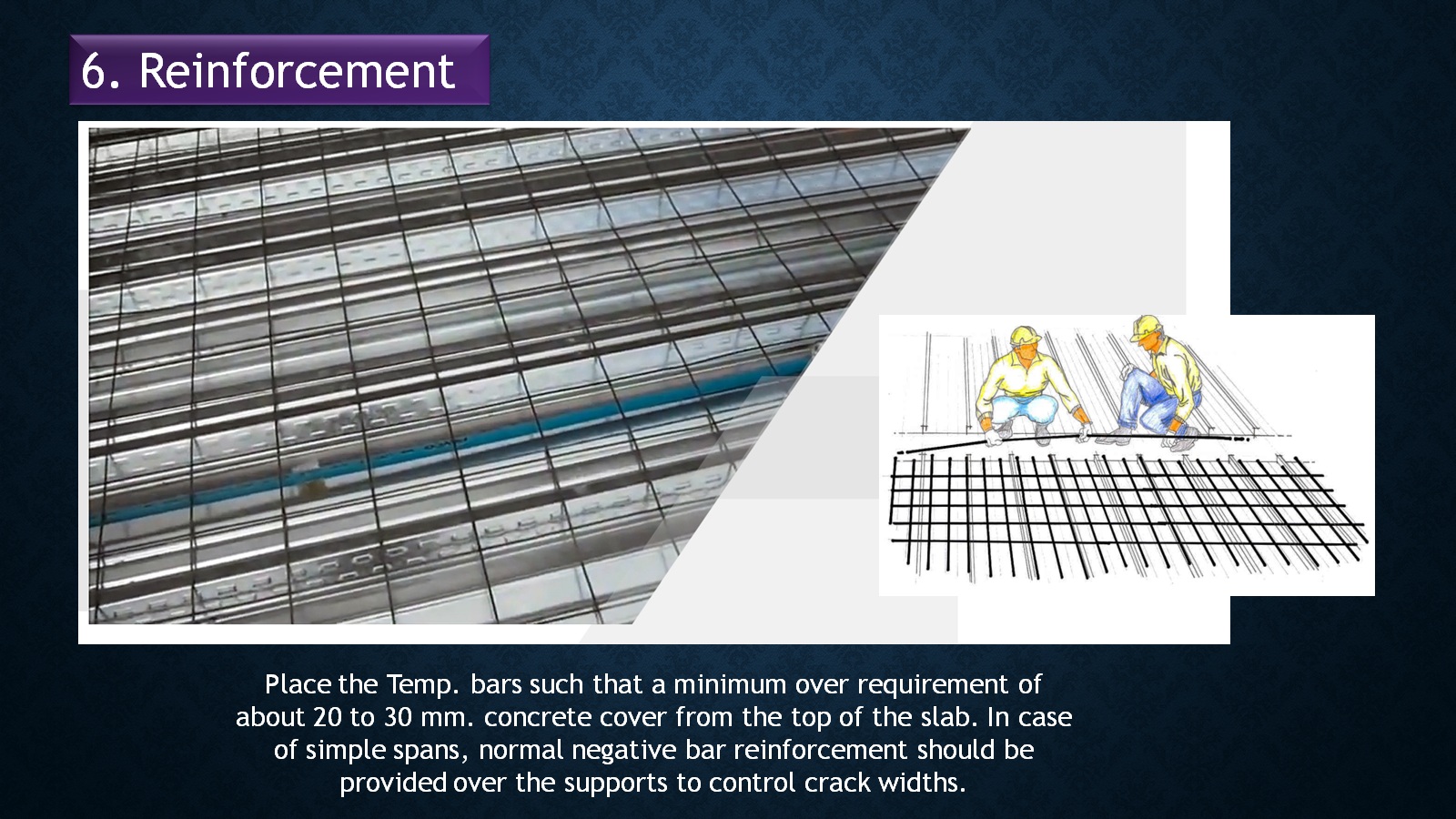

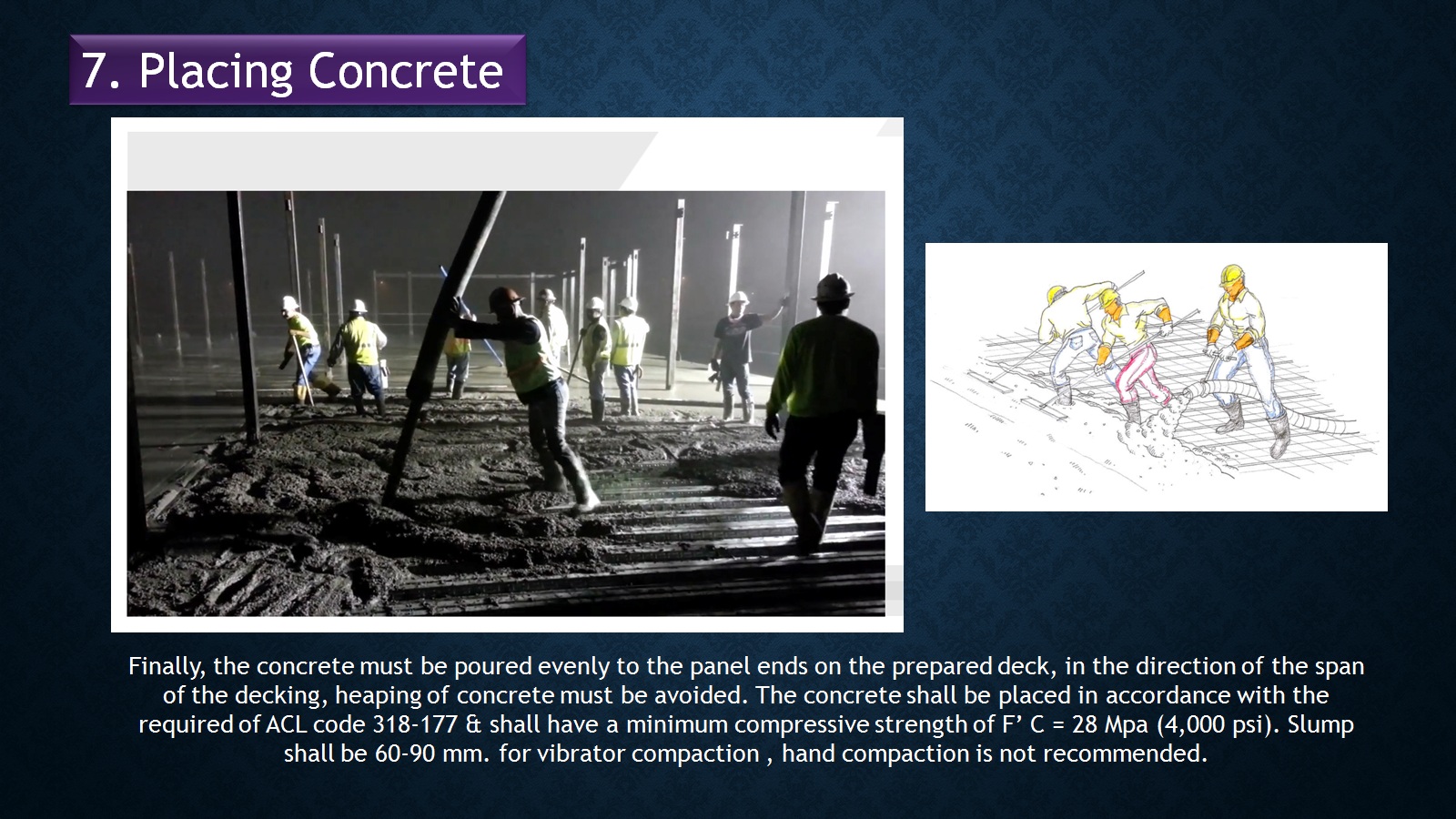

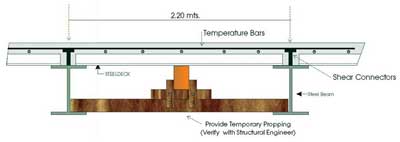

METHOD OF INSTALLATION AND DETAILS

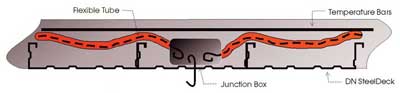

Propping and Electrical Layout

Connection Details

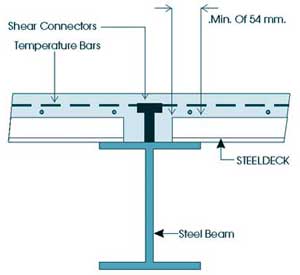

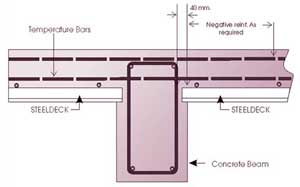

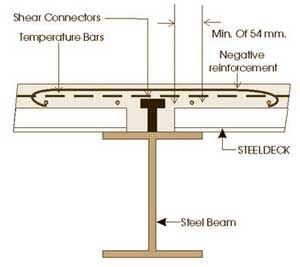

Composite Construction

COMPOSITE CONSTRUCTION

All reinforced concrete are composite construction in the sense that they combine two dissimilar material in any structural member. The term composite is usually applies to the combination of the concrete with structural steel in the form of DN Steel Deck Panels. The structural steel, while capable of carry loads when acting alone can develop much strength and stiffness if it acts integrally with the concrete.

DN STEEL DECK REINFORCED COMPOSITE SLABS

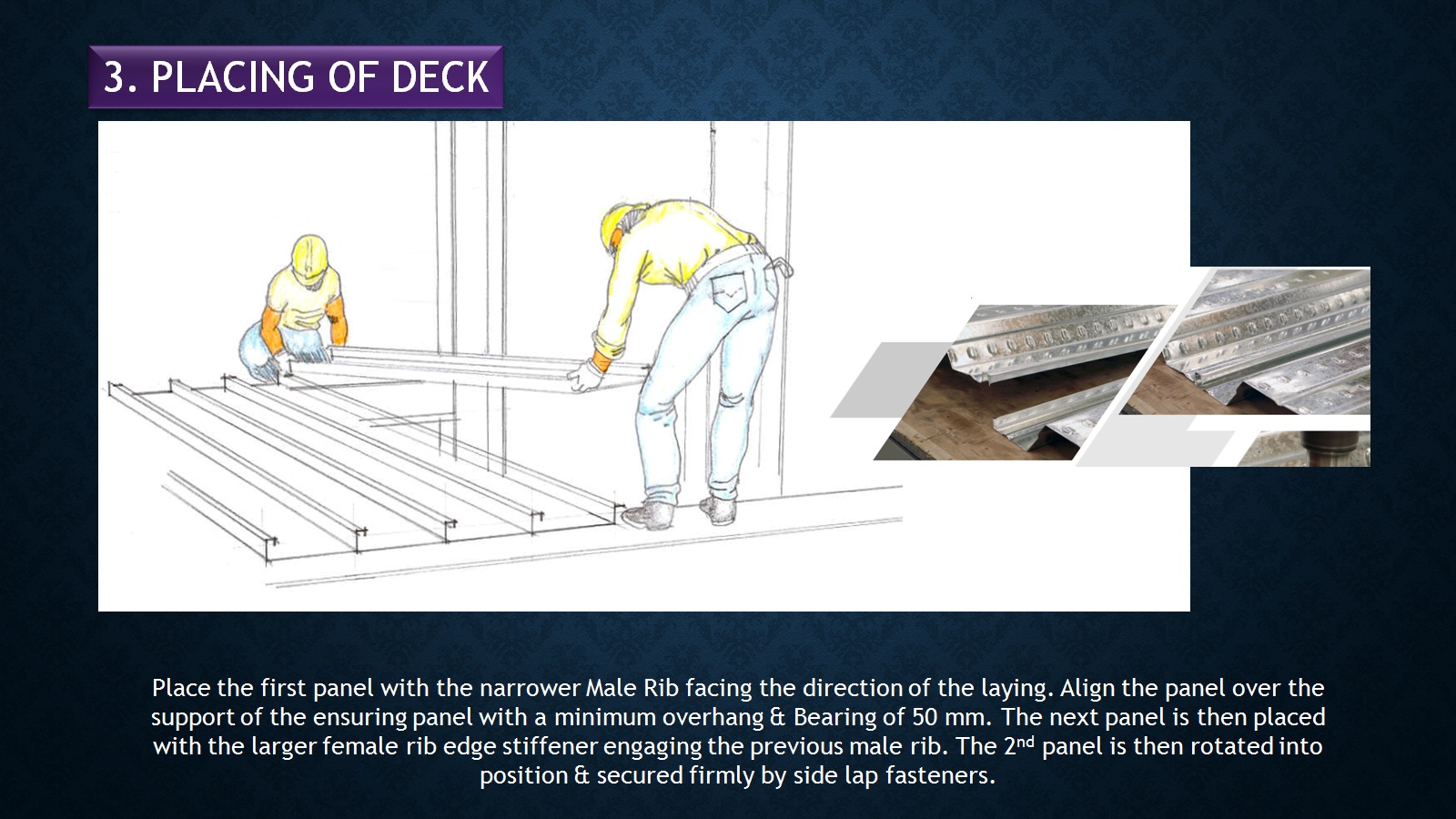

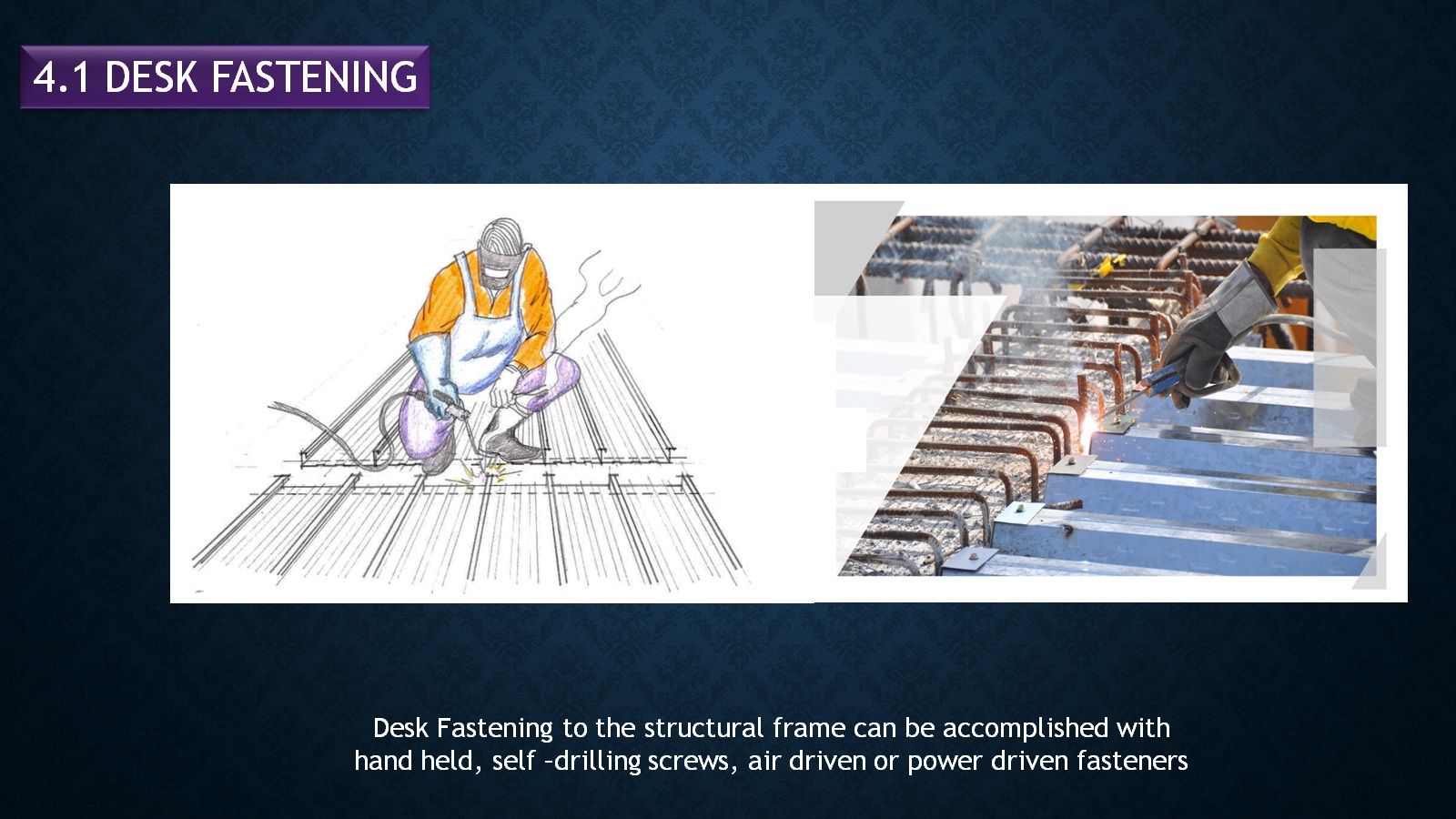

Floor and slabs, incorporating cold formed DN Steel Deck Panels, which servers both as form and reinforcement for the concrete placed over them, are widely use in the building where the main framing is either steel or composite construction. DN steel deck has a base metal of ASTM 446 cold rolled, 550 mPa (80,000 psi) yield strength and available thickness of 0.80 mm, 1.0 mm and 1.2 mm with zinc coating of Z-27.

DN Steel Decking, easily and quickly laid on a steel floor beams, serves as working flatform to support construction activities and to carry freshly poured concrete. This eliminates the need of temporary flaseworks and forms.

Reinforced Composite Slabs

COMPOSITE CONSTRUCTION

All reinforced concrete are composite construction in the sense that they combine two dissimilar material in any structural member. The term composite is usually applies to the combination of the concrete with structural steel in the form of DN Steel Deck Panels. The structural steel, while capable of carry loads when acting alone can develop much strength and stiffness if it acts integrally with the concrete.

DN STEEL DECK REINFORCED COMPOSITE SLABS

Floor and slabs, incorporating cold formed DN Steel Deck Panels, which servers both as form and reinforcement for the concrete placed over them, are widely use in the building where the main framing is either steel or composite construction. DN steel deck has a base metal of ASTM 446 cold rolled, 550 mPa (80,000 psi) yield strength and available thickness of 0.80 mm, 1.0 mm and 1.2 mm with zinc coating of Z-27.

DN Steel Decking, easily and quickly laid on a steel floor beams, serves as working flatform to support construction activities and to carry freshly poured concrete. This eliminates the need of temporary flaseworks and forms.

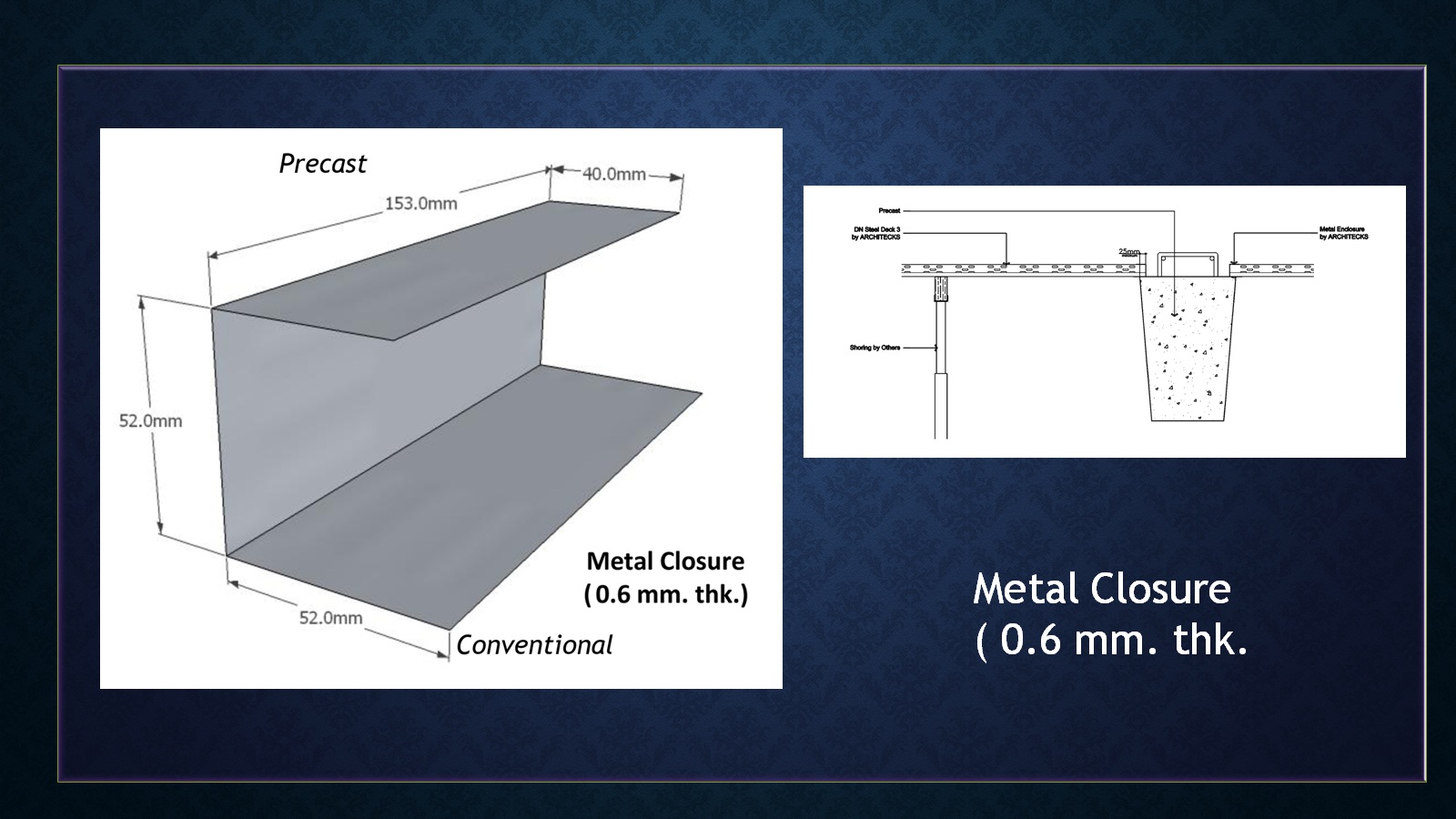

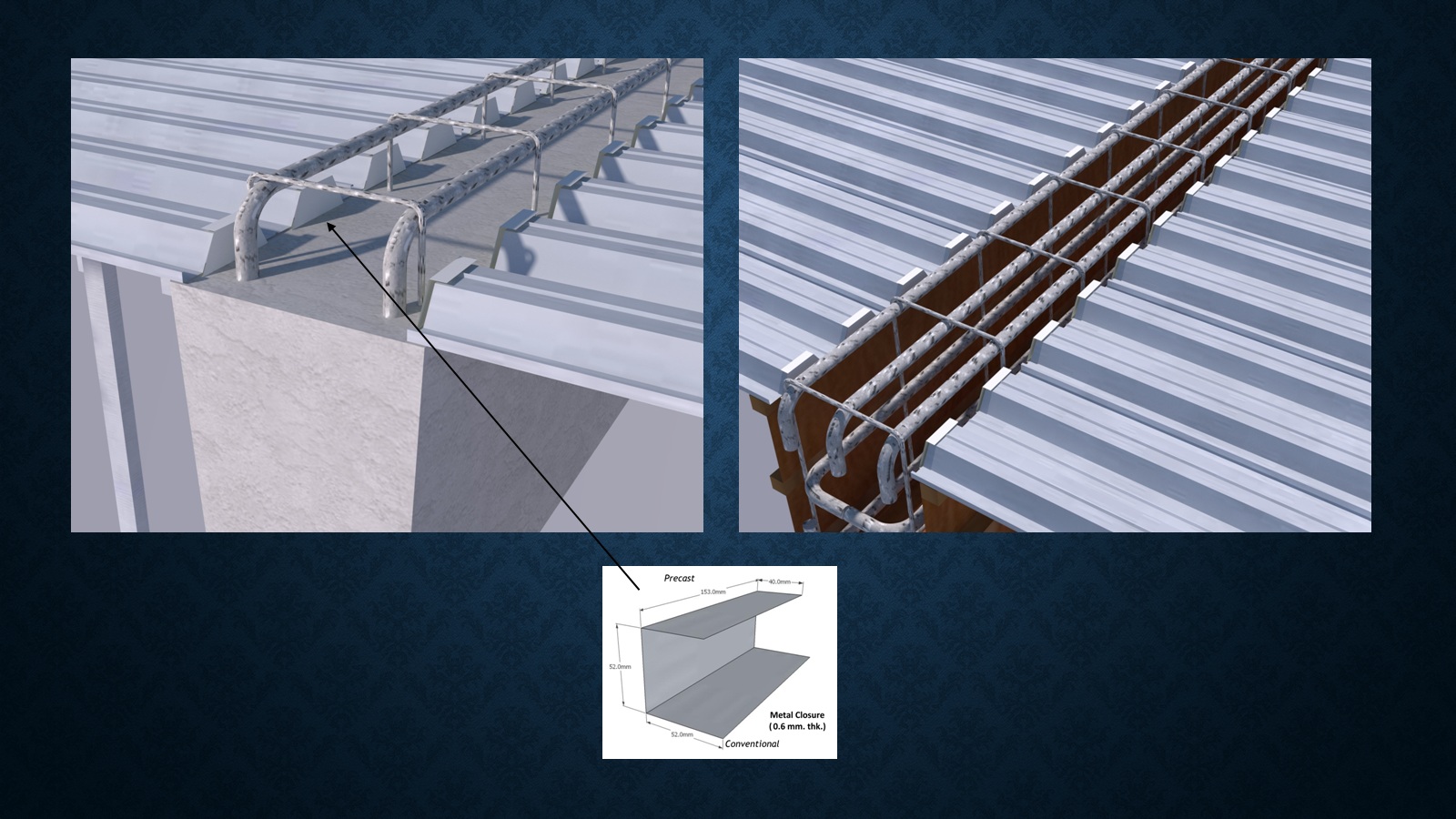

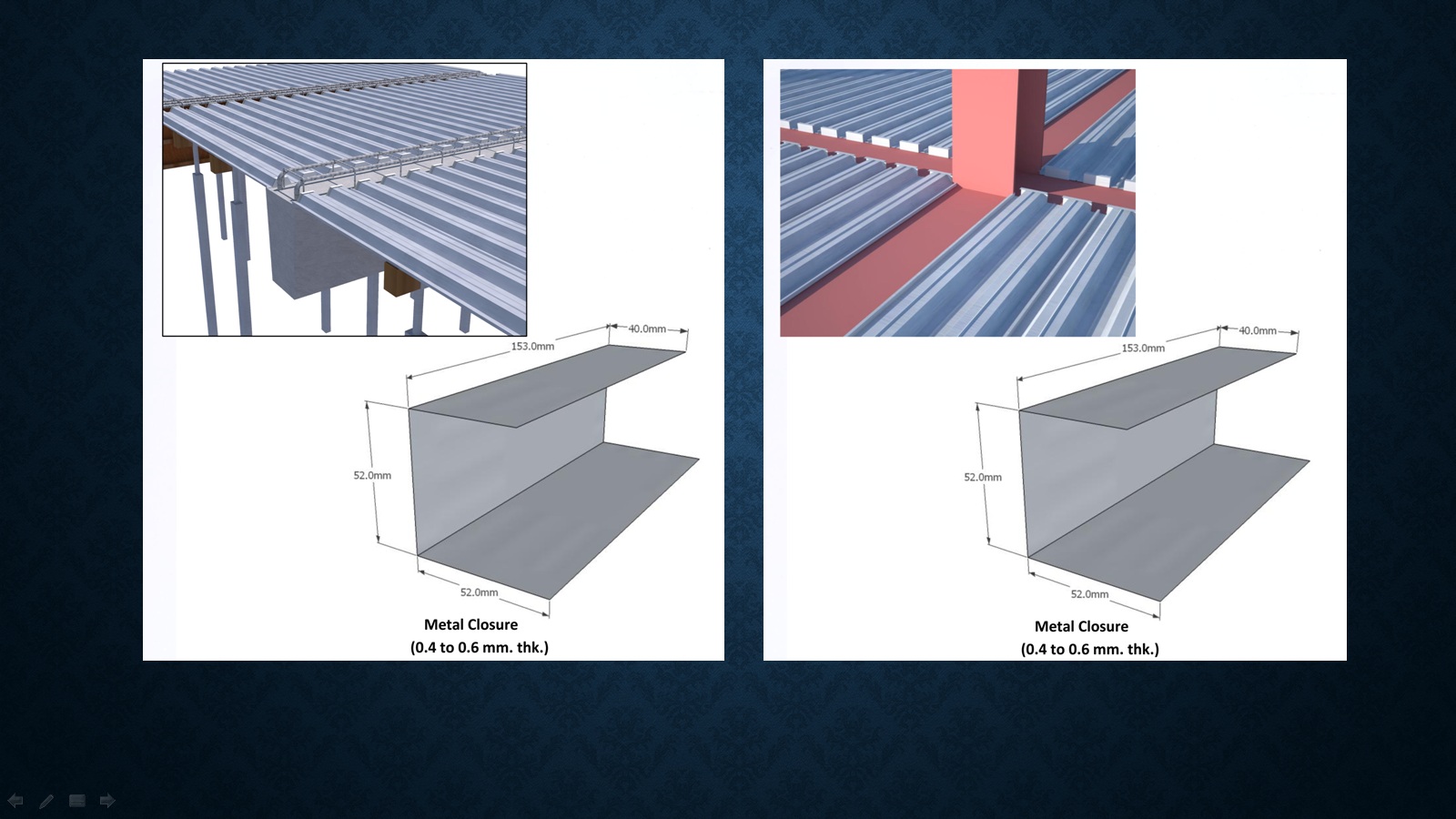

STEEL DECKING ACCESSORIES

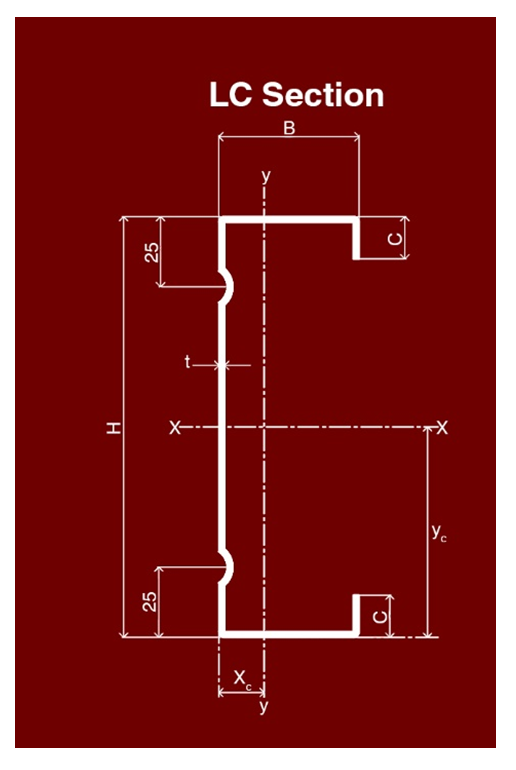

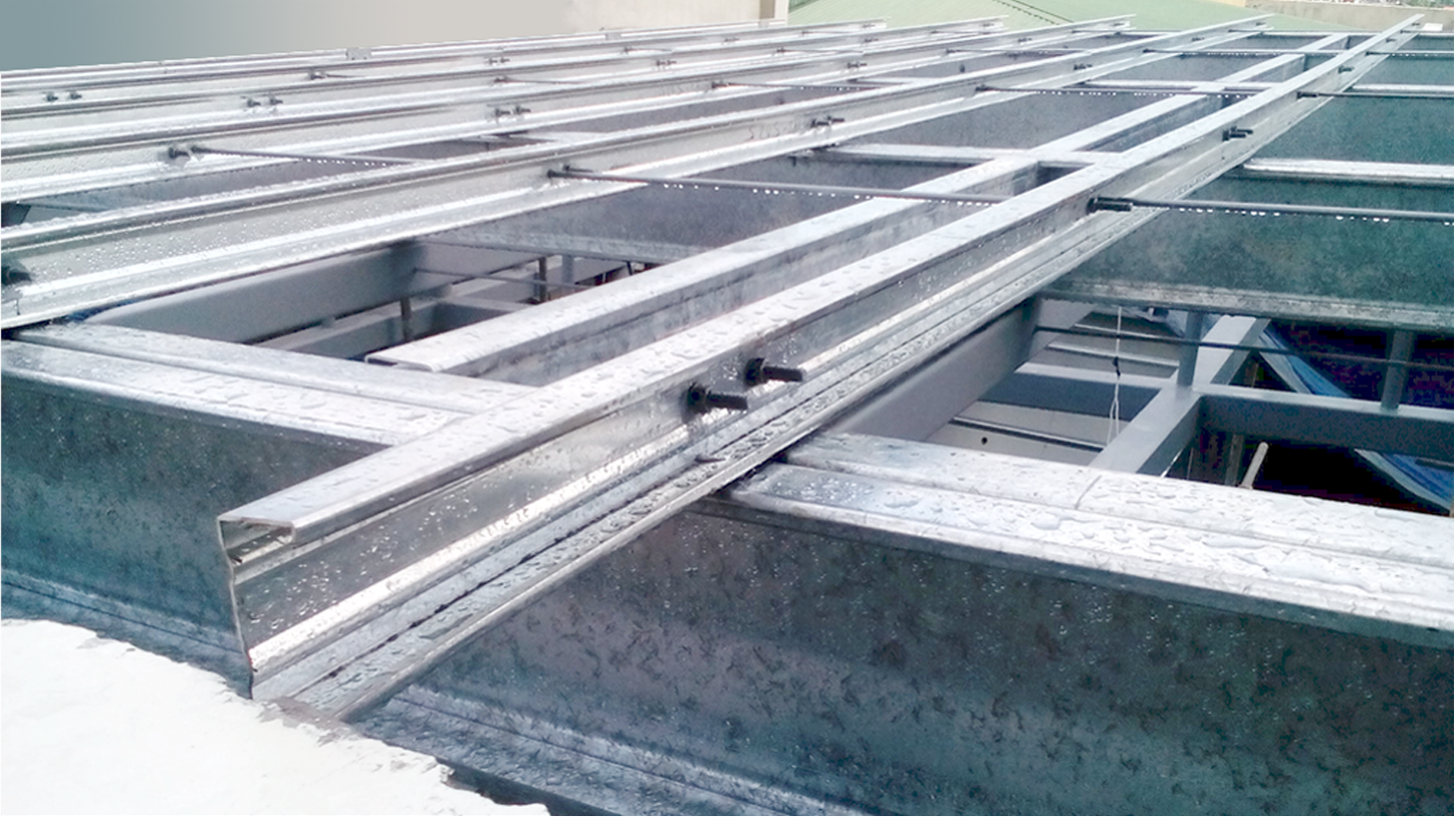

C Purlins

C Purlins are horizontal structures that are used to support the load from the roof or the sheathing. The plane surface of this purlin on one side has made it a preferred material for cladding due to its easy installation on concrete structures or steel. Our range purlins are light in weight and perfect for simple span construction.

- Optimum quality

- Easy installation

- Cut to size

- High tensile strength

- Abrasion & corrosion resistance

Advantages of C Purlins:

- Ability to span length

- Purlin erection is easier than others

- Fast to erect and easy handling

- No side drilling/cutting required

- Assured dimensions and straightness

- High durability, versatility and uniform quality

- Low transportation cost due to decreased weight

- Close tolerances on sectional sizes due to process of cold roll forming

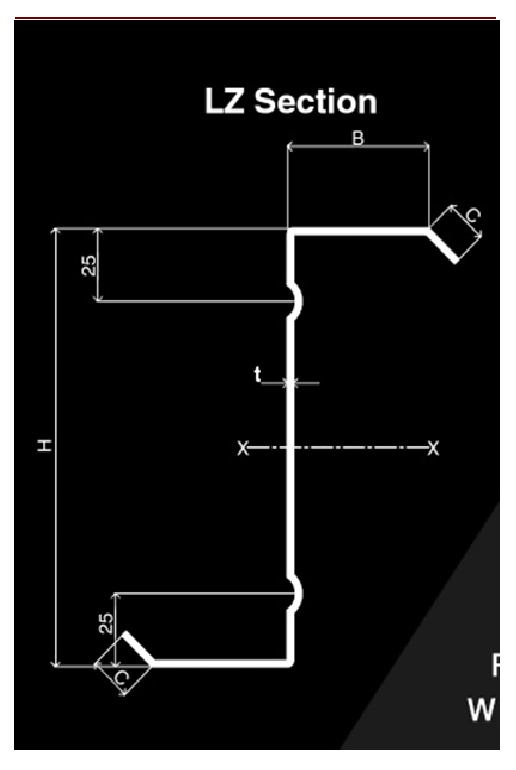

Z Purlins

Z Purlins are made using cold-formed or rolled sheets for supporting roof. The flexible shape of these beams facilitates various designs solutions. These purlins are extensively used in huge roofing solutions such as godowns, workshops, industrials sheds and many more. The range is known for saving upto 50% on structural sheet in comparison with hot rolled angles. Our purlins are crisp and clean in design and do not allow the scope of inaccurate lengths.

- Ability to span length

- Fast to erect and easy handling

- Assured dimensions and straightness

- Purlin erection is easier than others

- High durability, versatility and uniform quality

- Low transportation cost due to reduced weight

- Close tolerances on sectional dimensions owing to process of cold roll forming

- Saving up to 35-40% in weight and 20% in cost when compared to hot rolled purlins

Why use steel purlins?

- Steel is generally cheaper than wood construction

- Steel is recyclable and thus “greener” than wood

- Steel structures can be assembled quicker than wood

- Steel is lighter than wood structures of the same size

- Steel is not affected by termites or other insects that feed on wood

- Steel can be expected to last much longer than wood in most applications

- Steel has greater fire resistance than wood

Materials Specifications

- Hot-dipped zinc-coated steel

- Conforms to AS 1397/G275/G340

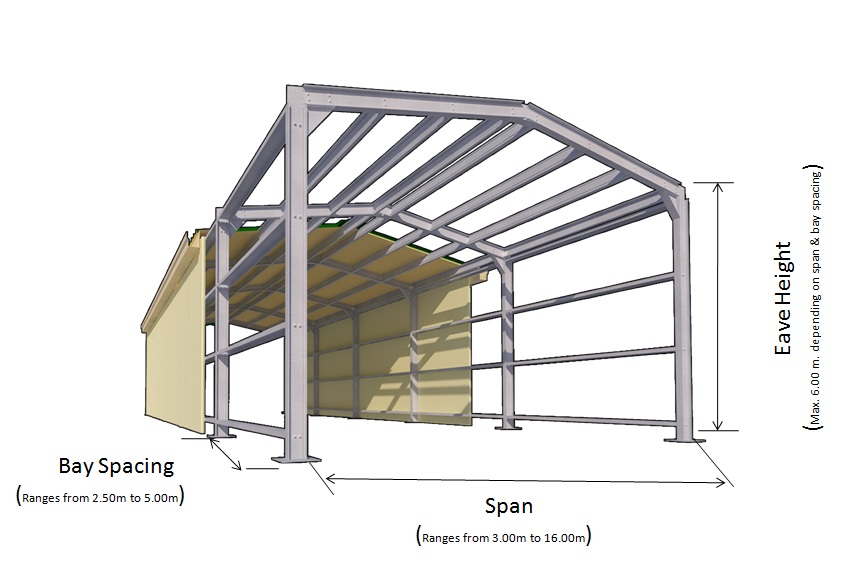

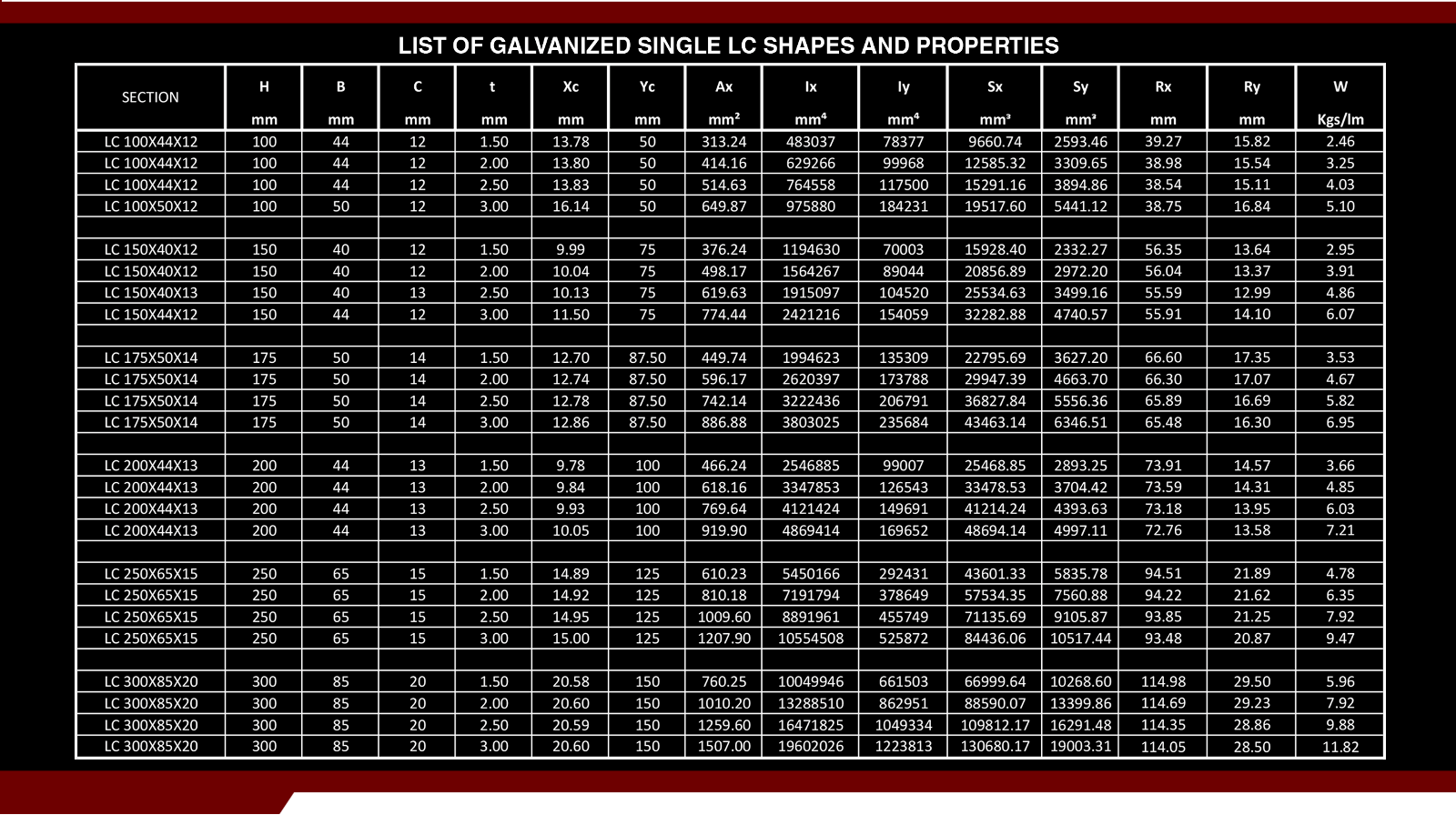

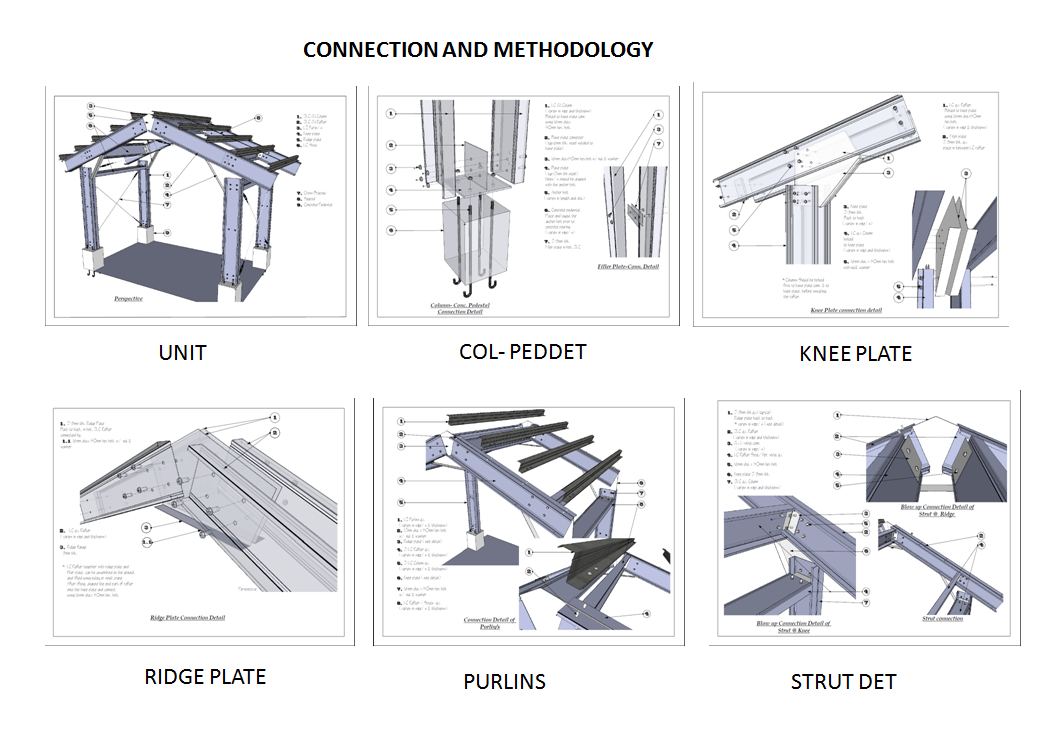

WHAT IS AISSI?

- SAVE ON THE COST OF BUILDING MATERIALS

AISSI Pre – engineered Rigid Frame was developed to serve the needs of the building industry requiring structures with unsupported spans of not more than 16m width. Building dimensions of this type fall in the region where the use of conventional steel construction method, such as welding of rolled or built – up structural shapes, becomes uneconomical. With the use of hot- dipped, galvanized light gage steel for the primary members of the structure such as that of AISSI Pre- engineered Rigid Frame, substantial savings can be achieved as compared with other systems.

- SAVE ON TIME AND COST OF ERECTION WORK

Components of AISSI Pre – engineered Rigid Frame are accurately shop – fabricated and assembled at site using all – bolted connections. No expensive jobsite welding and oxy – acetylene torch – cutting works. Roofing and wall cladding panels are delivered cut-to-size for quick enclosure of the building shell.

- ADAPTABLE TO VARIOUS BUILDING APPLICATIONS

Constructions of large un- obstructed floor space such as those needed for school buildings, agricultural facilities, filed offices, covered garage, temfacil, mass housing etc.

- WIDE RANGE OF CHOICES FOR BUILDING ACCESSORIES

Various choices for doors, windows, thermal insulation materials, roofing and cladding skins are available to suit your requirements.

Product Features

- Rollformed to various dimensions from a depth of 100mm. to 300mm.

- Available in the following thicknesses: 1.5mm.,2.0mm.,3.0mm.,3.5mm.

- Can be ordered cut to length subject to volume and transport limitations.

Advantages

- No need to paint.

- Highly compatible to use with long span pre-painted roofing materials.

- Since AISSI Hi-TEN LC Shapes can be ordered longspan, sections can be analyzed as multi-supported continuous members resulting in lower flexural stresses. Compared with simply-supported members, AISSI Hi-TEN LC Shapes are therefore safer and more economical to use.

- Unlike B.I sections, AISSI Hi-TEN LC Shapes do not have rust-staining problems.

Applications

- Can be used in residential, commercial, and industrial projects requiring hygienic and long term lifespan.

- Highly adaptable in agriculture & livestock industry such as poultry houses, piggeries, etc.

- Highly recommended to use in corrosive environments such as in food processing facilities, etc.

- Ideal to use in recreation and resort facilities exposed to salty air.

Architecks Metal Systems Inc

Architecks Metal Systems Inc