Aluminum Composite Panel

Aluminum Composite Panel

AMSI Aluminum Composite Panel (ACP) is made up of two layers of aluminum skin on the top and bottom, and one layer of anti-toxic polyethylene material in the core. Also, the skin surfaces can be coated with special paint material like PVDF resin or Polyster resin under a specific temperature condition.

2.) What application can AMSI ACP are used?

- Wall curtain, Cladding and Facade

- Roof Edges and Parafet walls.

- Dado, Walls and partitions.

3.) What is the standard size available?

- 1220 (width) x 2440 (Length) x 3 (Thickness) M.M.

- 1220 (width) x 2440 (Length) x 4 (Thickness) M.M.

4.) What is the maximum width and maximum length?

The maximum width is 1550mm, and the maximum length is 6000mm.

5.) What are the thicknesses of AMSI panel?

We offer 3mm and 4mm AMSI panels.

6.) How long does it take to match a custom color?

Our color matching process normally takes a week. A sample is preferred when a color match is requested. Also we can match the color as per international color charts, such as RAL color.

7.) How does AMSI ship our panels?

Our policy at this time is that all orders ship from our facility in Shanghai, China to destination port under FOB, C&F, and CIF terms.

8.) What is the minimum order?

600sqm for our standard color, 1000sqm for special color;

9.) How long is your delivery time?

Normally we can mobilize upon clearing of check.

10.) Why does PVDF coating possess such excellent performances?

The structure of fluorine-carbon short bond combined with hydrogen bond is the steadiest and firmest structure among all kinds of chemical bond structure. As one of the criteria of judging stability and tightness of chemical structure, the electronegative atom index of PVDF coating could achieve 105 KJ/mole. However, for the normal coating, it is only 83.2 KJ/mole. Also, there is an inorganic material whose molecular structure is SiO2, which is created by certain chemical method and made of pure inorganic resin. Because the energy of composing Silicon and Oxide is 101KJ/mole, this kind of molecular structure will not be destroyed easily by ultraviolet radiation. Moreover, the other properties of PVDF coating, such as self-cleaning, Incombustibility, environmental protection etc., are still remarkable.

11.) What is the advantage of NANO coating?

The NANO coating is an additional coating based on high-tech paints with property of anti-graffiti, anti-scratch and self-clean when it is used for every AMSI PVDF colors. Its outstanding function is anti-abrasion, anti-salt, anti-moisture and UV-resistance. In image, it will be shinier than normal PVDF coating. So it will make your building shinier, cleaner and reduce the maintenance cost too. And it is also used for AMSI polyester colors.

12.) How to examine the quality of protective films?

Film thickness 0.08mm, black inside and milky white outside. The degree of transparency of protective film should be very low. Also, when the film is being torn from rubber layer, the sound is usually low, the gloss of rubber layer is low, and the string is usually long and white; whereas, when the film is being torn from the acryl layer, the sound is generally high, the gloss of rubber layer is high, and the string is very short. Surely, what mentioned above is only used for reference, and could not be the final judgment, which must be tested by the specific devices.

13.) How to identify the quality of AMSI ACP?

AMSI Aluminum composite panel (ACP) is a kind of new decoration building material for exterior and interior wall. There are many different brands and different quality in the market; it is hard for consumer to identify the quality of AMSI ACP. So we advise you to use the following methods:

- Look over the surface of the panel; it should be smooth, no corrugation, without bubbling, flaw, and nick.

- Measure the panel; it should reach to the International Standard: Interior panel 3mm, Exterior panel 4mm.

- Bend the corner of the panel, if easy to be ruptured, it is not real PE, or bad PE

- Light the PE, if it is completely burned, its real PE; if impurity exists, it is bad PE

- Slot the panel, if it is ruptured, it is bad

- Drop a blob of Methyl Ethyl Ketone on exterior panel(PVDF), then rub out the reagent after 5 minutes, if see the aluminum skin, it is not PVDF coating.

- Drop a blob of Xylene on interior panel (Polyester), then rub out the reagent after 5 minutes, if see the aluminum skin, it is not Polyester coating;

- Ask for Quality Test Report and Warranty Certificate, ISO-9001 Quality System Certificate, which normal manufacturers obtained these certificates.

14.) What are the benefits of using AMSI panels?

AMSI panels offer the user superior flatness, excellent color uniformity while being lightweight yet durable as well as easy to work with. AMSI will shine your building.

AISSI

AISSI

1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm

WHAT ARE THE ADVANTAGES OF AISSI PURLINS?

No need to paint, highly compatible to use with long-span pre-painted roofing materials, and unlike BI sections, AISSI Hi-TEN LC Shapes do not have rust-staining problems.

WHAT IS THE USE OF ZINC COATING?

Application of a protective zinc coating to steel or iron, or also called galvanization, is done to prevent steel or iron from rusting.

MAXIMUM SPAN?

AISSI Pre-engineered rigid frame was developed to serve the needs of the building industry requiring structures with the unsupported spans of not more than 16m width.

INSTALLATION DETAILS?

Components of AISSI Pre-engineered rigid frame are accurately shop-fabricated and assembled at site using all bolted connections. No expensive jobsite welding and oxy-acetylene torch-cutting works.

Steel Decking

Steel Decking

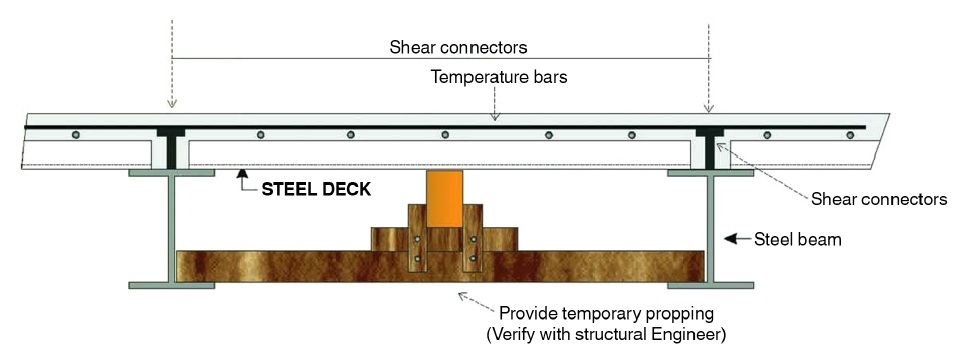

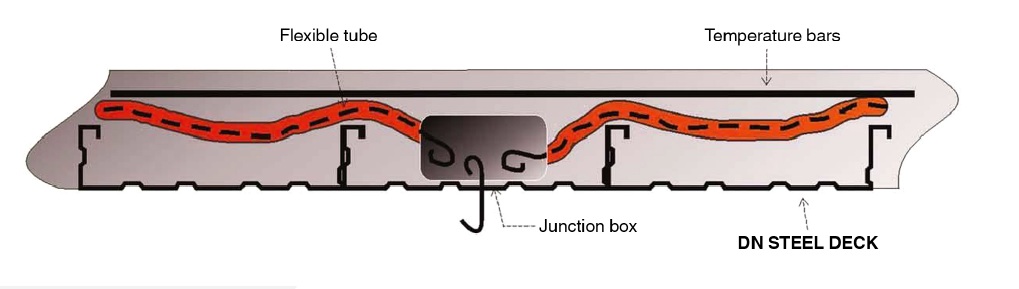

DN Steel Decking, easily and quickly laid on a steel floor beams, serves as working platform to support construction activities and to carry freshly poured concrete. This eliminates the need of temporary forms.

What application can DN Steel Deck be used?

It is used to support concrete or insulating membrane of a roof. It was developed to provide a structurally efficient product for use in roof and floor systems.

Advantages of DN Steel Decking compared to conventional method?

Saves time and cost, easy installation, structural stability with less weight, safe method of construction, attractive appearance and sustainability.

How long will it take to deliver the DN Steel Decking?

DN steel decking system only takes two (2) to three (3) working days from date of order.

What are the thicknesses of DN Steel Decking?

0.75mm, 0.80mm, 1.00mm, 1.20mm & 1.60mm (for DNSD 3 only)

Propping Layout?

Electrical Layout?

Connection Details?

*** See connection detail layout

Advantages of Web-Type DN Steel Decking?

Due to its ribbed design, DNSD 3, DNSD 4, and DNSD 5, help reduce the volume of concrete required for the slab without compromising the strength of the structure.

Advantages of Flat-Type DN Steel Decking?

DNSD 1 and DNSD 2’s flat soffit design provides perfect ceiling system.

Architecks Metal Systems Inc

Architecks Metal Systems Inc